Why Continuous Valve Monitoring Matters More Than Ever?

An ARC study reported that:

“The cost of performing predictive maintenance on valves can be up to five times less expensive than preventive maintenance and 10 times less expensive than corrective maintenance, even before the costs of downtime are figured in.”

And yet, these are often not monitored. With a scarcity of trained engineers, this becomes even more critical.

Control Valve App for Engineers

Digital Automation Engineers

Accelerate your digitalization journey with tangible results after a few weeks.

Maintenance Engineers

Reduce control valve unplanned downtime and gain more control over maintenance planning.

Process Control Engineers

Keep your processes running smoothly and proactively assess potential risks with control valves.

Reliability Engineers

Get valuable insights for replacement planning.

Inside the Control Valve App

As Seen in Valve World – April 2025

UReason is featured in the April 2025 edition of Valve World Magazine, where we team up with Yara International to showcase a real-world application of predictive maintenance at scale. The article highlights how combining our Control Valve App with Yara’s AnomaliSense™ platform is helping drive reliability and reduce unplanned downtime across their operations.

Trusted by Global Customers

UReason started in the Oil & Gas Industry and over the years expanded to other markets including Chemicals, Energy, Defense, Infrastructure, Manufacturing, and more.

Maximize the value of your valves

The Valve App creates value for Maintenance, Reliability Management, and Operations. Here are five ways you can benefit from it:

- Reduce energy/product losses

- Plan investments more accurately

- Optimize maintenance planning for shutdowns

- Minimize on-site inspections

- Lower risks by getting early warnings

Discover all about the Control Valve App in one brochure

Our Control Valve App is an intelligent solution that makes it easy to monitor and optimize the performance of your control valves. With real-time monitoring and analysis, the app can identify potential problems before they occur, reducing downtime and saving you money.

Download our brochure to learn more about how the Control Valve App can transform your valve maintenance and operations processes.

The Valve App is easy to integrate

UReason Valve App is a brand-agnostic valve monitoring solution that supports many valve brands and is easy to integrate with many data platforms and CMMS. It connects to many data sources, providing a comprehensive view of valve health and performance.

- Plug-and-play

- Supports Air/Electrical actuators

- Benchmarks valve performance

Get continuous insights into your valves in real time

Asset management perspective

- Determining asset (valve and actuator) Remaining Useful Life for better maintenance and Capital Expenditure planning.

- Real-time insights for quick response and proactive maintenance.

- An automatic connection to CMMS that creates automated work processes.

Reliability management perspective

- Detailed (graphical) insights on valve behaviour for deep understanding.

- Root-cause analysis models for dysfunctions.

- Benchmarking over the total asset base.

Operations perspective

- Additional insights for product/energy loss.

- Reduce Fugitive Emissions by addressing stiction, stick&slip and stem/packing issues

UReason x Evonik Antwerpen

This use case explores how Evonik Antwerpen, a major specialty chemicals production site, implemented UReason’s Control Valve App (CVA) to enhance valve maintenance and reliability. With numerous critical control valves, Evonik sought to avoid costly production downtimes and improve turnaround planning.

Compare plans

Choose one of the three options and find what fits for you.

Control Valve App

Valve App Basic

Valve App Premium

Valve App Enterprise

Plans

Fill in the form below to know more about our options.

Valve App Basic

Based on batch data and automated monthly reporting (pdf)

- Valve Health Status

- Failure Detection

- Benchmarking of your assets

Valve App Premium

Based on historical or streaming data (cloud) and integration in CMMS/ERP systems (REST API)

- All basic features

- Streaming Data Connection

- Automated Work-Orders

- Live Dashboards

Valve App Enterprise

Based on streaming data and integration in CMMS/ERP systems connect your control valves with other assets and processes

- On edge, on premise or on cloud

- Combinations of equipment

- Integration with other systems

- Additional Sensors

- Monthly reviews with subject matter experts

Choose Your CVA Plan

Fill out the form below to choose the best plan for your specific needs, and our dedicated team will get in touch with you promptly. Whether you’re looking for basic monitoring or advanced predictive maintenance, we’ll help you find the perfect solution to enhance your operations and maximize efficiency. Contact us today!

Get Started with the Control Valve App

Don’t miss out on this opportunity to improve your operations with real-time data and actionable insights. Try our Control Valve App Demo today.

What brand and type of valves and actuators are supported?

UReason supports all brands: air, electrical and electro-hydraulic actuators in combination with globe, needle, and gate valves. We also support most butterfly valves.

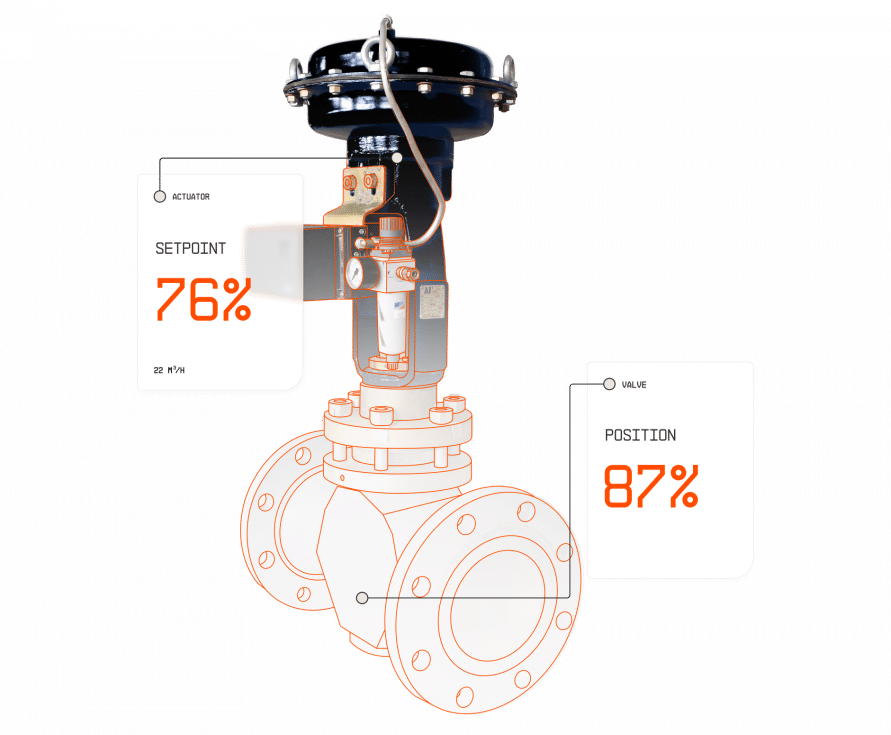

What data is needed for the Valve App?

Setpoint and Output (Valve position) of the controller of the control valves. If position feedback is not available, additional data on controlled measurement flow/level/pressure/temperature and environment is needed.

What meta data of the valves/actuators is needed?

Actuator and valve (model and make) and installation dates. If not available, we need to create an asset inventory.

How much data do I need to provide?

For the basic version, you can provide up to one month of data. We recommend a minimum of one week of continuous data.

How do you generate a work-order in the CMMS?

The valve app provides a REST Server that will list/provide the recommendations/orders for your assets. You can easily integrate this with your CMMS – IFS/Ultimo/SAP/MAXIMO/Upkeep. All have a capability to interface to our REST Server and have REST-APIs to generate work-orders for the functional items. We can also connect with most of the own build CMMS, please contact us for the details.

How does the Control Valve App differ from traditional process control systems and loop-tuning solutions?

The Control Valve App differs from traditional process control systems and loop tuning solutions by offering more insights from an asset management perspective and integrating with a CMMS. The app provides continuous information about the health of the asset, determines the remaining useful life, and automatically connects with your workflow. This makes control valve diagnostics very transparent and straightforward. It also provides multiple detailed insights for Reliability Engineers to better understand the condition and health of the valve, including root-cause analysis and benchmarking. In addition, the app offers insights for Process Control Engineers to calculate product and energy loss.