Big data, the internet of things and artificial intelligence have changed manufacturing in unprecedented ways. The ability to collect data from machines to monitor their condition and predict how they will behave in the future seems to be the final nudge towards reversing the stagnation in productivity seen in the last decade. By the year 2025, this innovation is expected to create $3.7 trillion in value.

Although early adopters claim overwhelming advantages because of predictive maintenance, asset owners and original equipment manufacturers have been slow in adopting the technology, largely because of lack of expertise and lack of belief. The lack of expertise is addressed by state-of-the-art Asset Performance Management solutions, but the lack of conviction is rooted in some basic misunderstandings that hold back asset owners and manufacturers from taking full advantage of the power of innovation. These beliefs have no basis, and companies that will dispel them before their competitors will get a larger share of the growing productivity pie than their competitors. The most common of these misbeliefs are rooted in the fear of cost.

Myth 1 – Asset Performance Management Is Too Expensive

Because of its cutting-edge nature, Asset Performance Management is presumed to be very expensive. Manufacturers fear that the cost of a condition-based monitoring and predictive analytics suite may be too high for their business to afford or that despite the savings it might bring, it would take very long to recover the expenses. That is not correct.

Firstly, Asset Performance Management applications can use existing data from your equipment and combine it with low-cost IoT sensors to monitor your assets and develop models to predict their behaviour. Secondly, the deployment cost does not increase with more modern communication options. On the contrary, they are decreasing with newer communication technologies such as 4G, LoRa, and NB-IoT. Compared to other technological innovations such as robotics, APM is inexpensive but has a huge cost cutting potential.

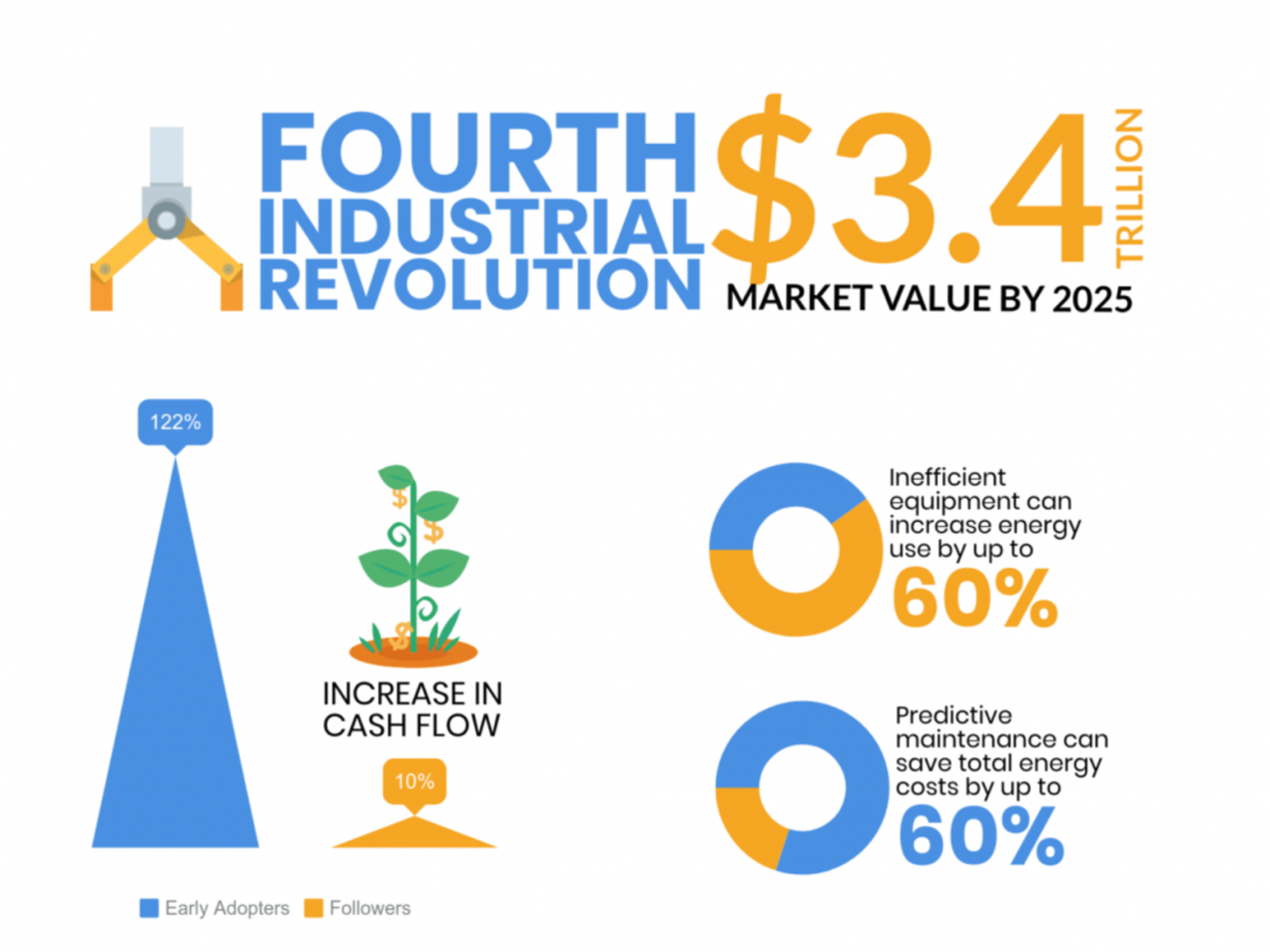

Some manufacturers realise that predictive analytics are essential to the future of manufacturing, but want to wait because they believe the prices are bound to come down as the market grows. This policy of waiting and following is not the way to save money. It is the visionary early adopters that will reap the most benefits of the emerging technology, with their cash flows increasing by 122 percent according to a study by McKinsey Global Institute. For those who follow them, this increase in cash flow would be only 10 percent.

Myth 2 – Predictive Analytics Are Only For Very Large Companies

Some manufacturers are hesitant to take advantage of predictive analytics because they think big data is only for big businesses. That impression has especially been dispelled in a study by the World Economic Forum of sixteen factories they designate as the most advanced in terms of their use of Fourth Industrial Revolution technology. They are referred to as lighthouse factories because of their pioneering position in the use of technology. One of them was a 250-person Italian company that was able to implement the changes without spending out of their limited budget, time and human resources. As their overall equipment effectiveness grew by 11 percent, their revenue also grew by almost 8 percent, “with limited investment by using off-the-shelf technology”.

These vanguard companies were not even exclusively multinationals from developed nations. Many of these them are located in China, Eastern Europe and the Middle East. Labour costs are increasing even in these locations, and the efficiency promised by predictive maintenance is as important for very large manufacturers as it is for small and medium sized ones.

Myth 3 – Sustainability Means Lower Profits

When it is said that asset performance management increases sustainability, some businesses take it to mean lower profits. It is because sustainability or energy efficiency are associated with the notion of giving up high profitability to protect the environment. But the sustainability that comes out of predictive maintenance is about much more than that.

Firstly, condition based monitoring allows asset owners to see which equipment is not working and optimum efficiency. Inefficient equipment can increase energy use by up to 60 percent. With predictive maintenance, energy costs can come down by 20 percent over a period of a year, according to a report by the US Department of Energy.

Secondly, sustainability means longer equipment life cycles because of optimum use and maintenance. For equipment manufacturers and maintenance service providers, that also means a stable long-term subscription-based stream of income that is not vulnerable to economic fluctuations. For asset owners, that means risk averse spending that is stable and not prone to accidents, unplanned downtime and unexpected failures. As unexpected equipment failures end, so do unnecessary and costly emergency deployments to their locations. Especially in cases where such plants are in remote locations, significant carbon emissions in unnecessary staff trips are avoided.

Predictive analytics will change manufacturing in a massive way in the coming years, increasing productivity and lowering expenses in sustainable ways. But most of the trillions of dollars in extra value that big data and AI will bring in are up for grabs for the early adopters – smart companies that can dispel limiting myths, envision the future, and invest in it to become industry leaders.

To learn more how UReason can assist you in transforming your business, download our brochure.

APM Software Brochure

Download our brochure to learn how APM could improve your operations, learn how the maintenance landscape is changing and find out the unique ways UReason can help you.