The ripple effect of unplanned control valve downtime

Control valve downtime has far-reaching consequences for industrial processes. When these valves fail or operate improperly, the disruption to fluid flow destabilizes the entire process, resulting in issues such as overpressure, high temperatures, leaks, and compromised product quality. Moreover, such downtime increases energy consumption, leading to higher facility costs, and poses safety hazards, including potential leaks or explosions.

If the control valve is critical to the process, its failure can bring production to a standstill, causing significant losses and further expenses. Neglecting control valves can be costly, even though they may not be the most expensive equipment in the process.

Ways to prevent unplanned downtime and extend the service life of valves

Regular maintenance and inspections

Schedule regular maintenance and inspections of the control valves to identify and address any potential issues before they lead to breakdowns.

Monitor the performance of the valves

Regularly monitor the performance of the control valves, including the flow rate, pressure, and temperature, to identify any inconsistencies that could indicate a problem.

Have a maintenance schedule

Have a preventive maintenance plan that schedules regular check-ups and maintenance of the control valves.

Use a specialized software

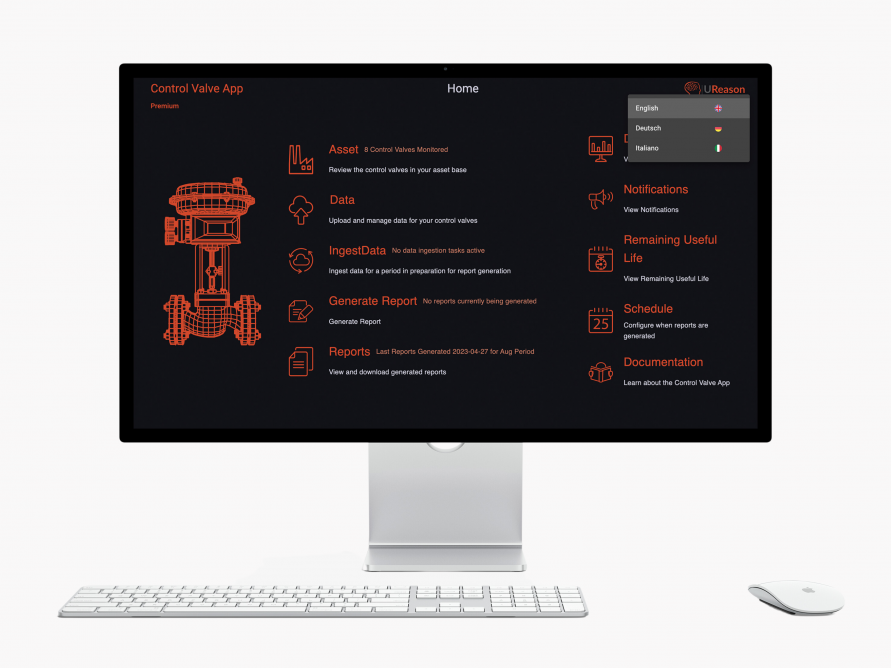

Use specialized software to analyze the performance of the control valves and provide recommendations for maintenance and repair. This is where the Control Valve App comes into play.

Control Valve App makes the difference

UReason’s Control Valve App not only helps reduce control valve downtime but also saves cost by limiting product/energy losses and gives you more control over maintenance planning and overall maintenance processes.

- Easy to implement, only setpoint and valve position data needed.

- Uses intelligent models that combine domain knowledge and AI to provide detailed analysis and recommendations for control valves that help identify problems early.

- With a flexible pricing structure, the maintenance personnel can start with small batches of valves and scale up easily.

A smarter solution for Maintenance Engineers

By leveraging real-time available data, as well as using AI-models, digital twin technology, and domain knowledge, our Control Valve App helps Maintenance Engineers proactively assess potential risks, optimize control valve performance, and prevent unscheduled downtime. The Control Valve App will show how your control valves are performing, what can be done better and where deterioration is taking place before it is too late.

Discover all about the Control Valve App in one brochure

Our Control Valve App is an intelligent solution that makes it easy to monitor and optimize the performance of your control valves. With real-time monitoring and analysis, the app can identify potential problems before they occur, reducing downtime and saving you money.

Download our brochure to learn more about how the Control Valve App can transform your valve maintenance and operations processes.