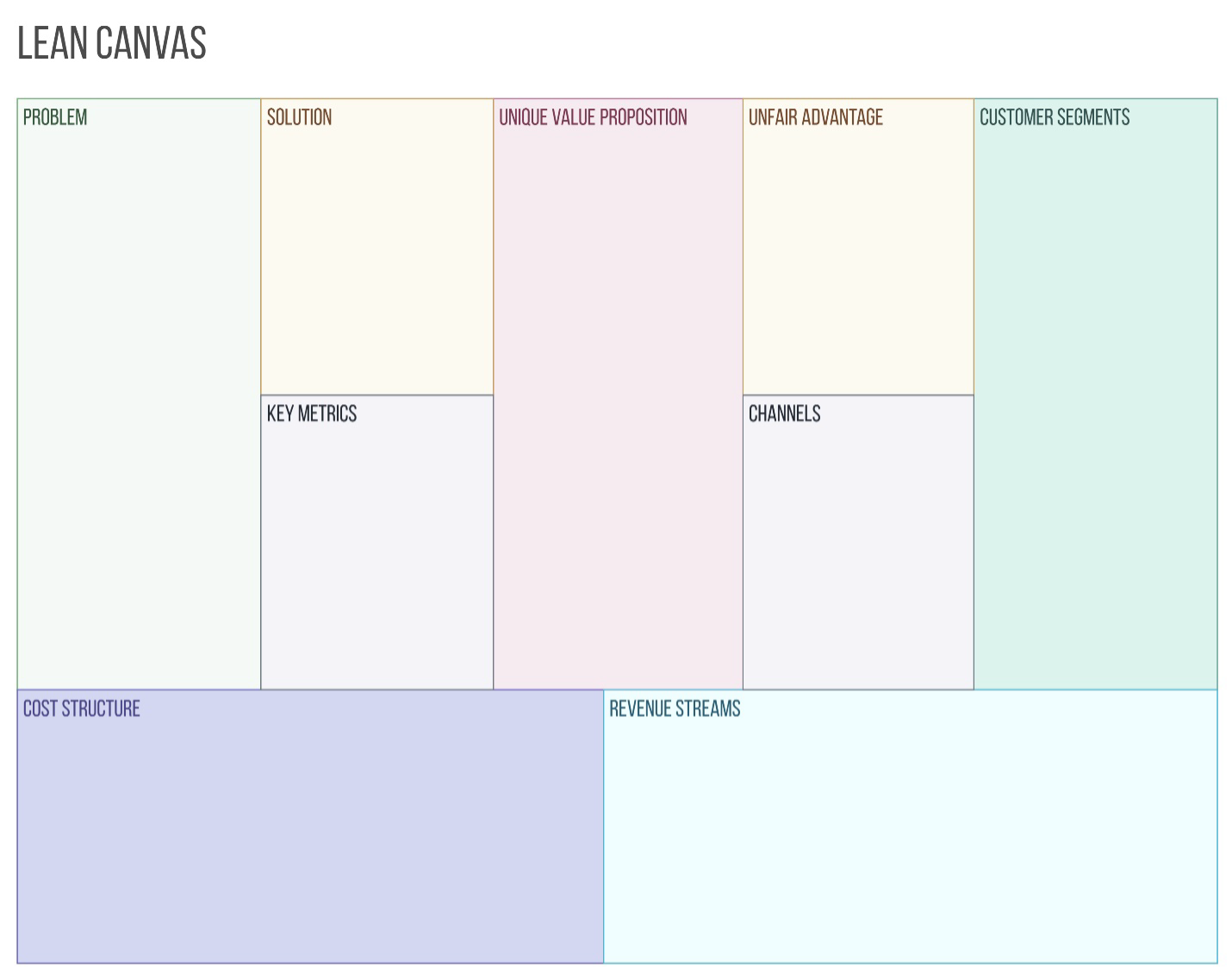

A Lean Canvas is a one-page business planning tool that helps teams quickly develop and document their business model ideas. It is particularly useful for new ventures such as your Digital Servitization Project, as it focuses on identifying and addressing key assumptions about the business, allowing for rapid iteration and testing.

The Lean Canvas was created by Ash Maurya as an adaptation of the Business Model Canvas (developed by Alexander Osterwalder), but with a stronger focus on startups and problem-solving.

Now setting up a Lean Canvas for a digital servitization product involves tailoring the Lean Canvas framework to address the specific challenges and opportunities of blending digital services with traditional product offerings. Digital servitization focuses on enhancing physical products with value-added digital services.

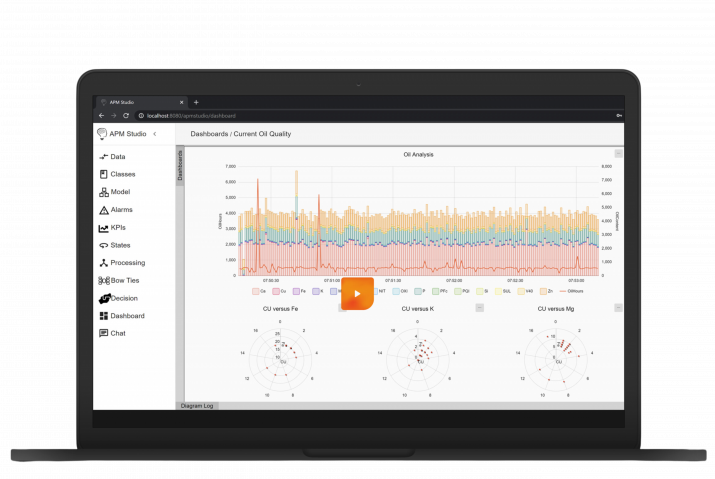

Using our Control Valve App, which is based on APM Studio, we provide you with an example, a step-by-step guide, to setting up the Lean Canvas:

-

Problem

– Define the key problems your target customers face.

– For digital servitization, focus on pain points related to:● Inefficiencies in managing physical assets.

● Lack of data-driven insights.

● High costs of maintenance or downtime.

● Limited integration between digital and physical systems.Example: Our customers in Refining, Chemical, Pharma, Oil&Gas all deal with a skill and staff shortage, aging assets of many different OEMs, valve and actuator performance which is off specification, issues that go unseen, random valve/actuator failures, and they struggle to determine remaining useful lifetime to plan for turn-arounds.

-

Customer Segments

– Identify your target customers and users. For servitization, these may include:

● B2B clients (e.g., manufacturers, operators).

● Decision-makers (e.g., factory managers, IT heads).

● End-users interacting with your digital service.Example: We have 3 types of customer segments for the Control Valve App:

a) Reliability, process and maintenance managers and engineers, aiming to minimize downtime and improve operational efficiency.

b) Innovation and digitization officers, that want to capitalize on the investments made into OT data lakes and create quick wins on the basis of data they facilitated to store (from technology to solution focus).

c) OEMs and Valve Services Providers who want to provide SaaS based monitoring options for their assets/customers, enabling them to optimize their service planning and extend their services offering. -

Unique Value Proposition (UVP)

– Clearly articulate how your product uniquely solves the problem.

– For digital servitization, emphasize:● Enhanced efficiency and productivity.

● Real-time monitoring and predictive analytics.

● Integration of physical and digital solutions.Example: One of the biggest UVPs of the Control Valve App is its ability to tap into the data the end-users already have in their data historians (like AVEVA PI, Aspentech IP21, Yokogawa Exaquantum etc.) and using this data monitor valve health and performance and providing insights into remaining useful life. On top off this the Control Valve App does this for many valve and actuator types independent of model and make. We found that our customers choose the Control Valve App for different reasons:

End users, asset owners and valve service companies:

a) For turnaround scope assessment.

b) To also monitor the less critical valves.

c) To change from reactive/preventive to proactive maintenance.

d) To save time in inspection and increase safety in the field.

e) To provide expert knowledge to new field technicians.

f) To reduce fugitive emissions.Digitization departments:

a) To provide, plug and play, solutions based on the OT data regionally/centrally collected easing the adoption of digital initiatives for operations/maintenance departments.

b) To accelerate data driven maintenance initiatives.

c) To validate technology stacks chosen for their fully owned or hybrid cloud initiatives.OEMS, valve/actuator manufacturers:

a) To provide more aftersales services.

b) To improve their products based on usage data from the field.

c) To have a closer relationship with the end customer, which is a great value in the control valve market as direct sales is often not the mainstream business model for OEMs. -

Solution

– Define the core features of your digital servitization product.

– Address how the product will deliver the UVP to solve the problems.Example: The Control Valve App:

a) Uses data already available/stored (no need for additional sensors).

b) Is vendor agnostic, i.e. control valve model and make independent.

c) Runs as SaaS (managed by UReason) or on-premises/in customer’s cloud.

d) Provides recommendations and root-cause identification.

e) Provides remaining useful lifetime -

Channels

– Detail how you will reach your customers.

– For digital servitization, consider:● Direct sales to businesses.

● Partnerships with equipment manufacturers or service providers.

● Online marketing or webinars for thought leadership.Example: For the Control Valve App, we do direct sales. This is important as valve services companies and OEMs look at how the CVA is adopted by end-customers. Next to this we partner with valve services companies, companies active in the domain of providing digital automation solutions and OEMs.

-

Revenue Streams

– Outline how your product generates revenue.

– Digital servitization typically leverages subscription or pay-per-use models.Example: For the Control Valve App, we use a monthly subscription for software access, which is based on the volume of control valves that are being monitored. In addition, we have a pay-per-insight/integration and deployment model (Basic, Premium and Enterprise), which based on the selection by the customer provides additional benefits and control over the Control Valve App.

-

Cost Structure

– Identify the major costs associated with delivering your digital servitization product.

– Include:● Development of digital platforms (e.g., software, AI models).

● Hardware costs (e.g., IoT devices, sensors).

● Maintenance and support services.Example: The Control Valve App is delivered in a subscription model. This model has different tiers for Basic, Premium and Enterprise. When the customer chooses Basic or Premium it is delivered as SaaS (Software as a Service) that includes hosting and management by UReason which is costed on the basis of the number of control-valves monitored.

-

Key Metrics

– Define measurable indicators of success. For servitization, focus on metrics that track both product usage and service impact.

Example: A bit of repetition to cost structure, but the Control Valve App uses a subscription model for the number of monitored valves based on the tier chosen. The Premium tier provides integration options for the customer to their EAM/CMMS and the option to stream data. The enterprise tier allows the customer to manage the Control Valve App on their own cloud/hardware.

-

Unfair Advantage

– Highlight what makes your solution difficult to replicate.

– For digital servitization, this could include:● Proprietary algorithms.

● Exclusive partnerships with manufacturers.

● Unique integrations with existing systems.Example: The Control Valve App is based on propriatary knowledge gained by UReason over years and combines both deterministic models and machine learning models to provide insights on valve performance and valve health.

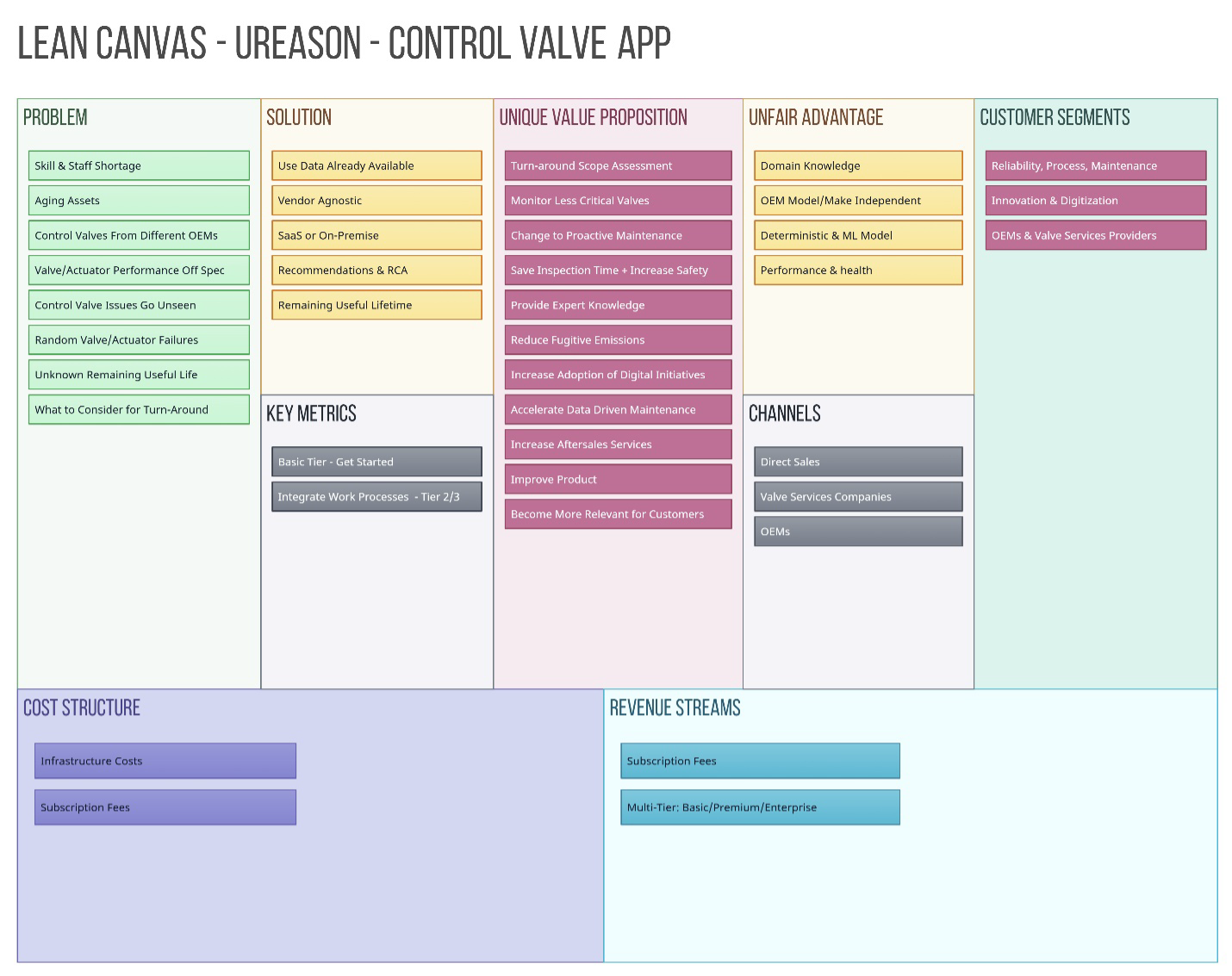

This concludes our step-by-step guide and examples for Digital Servitization Projects. Below is the completed Lean Canvas for the Control Valve App:

Looking for expert guidance?

Book a quick 30-minute call with Dr. Nicolas Spiegl, a chemical engineer who leverages his knowledge of technology and work processes to develop pragmatic digital solutions. He works with partners and clients in the process industry to reduce costs, increase efficiency, and innovate new business models.

Let’s explore how we can support your goals!