Industry 4.0 and the Automation Pyramid

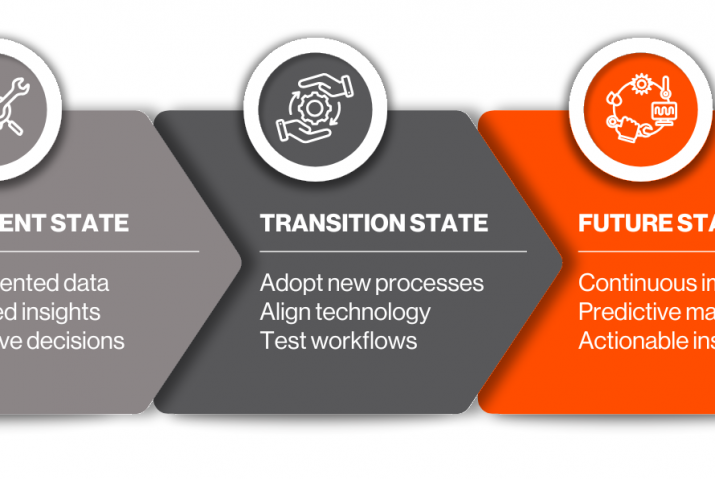

UReason’s APM Studio can monitor the condition of assets found at the field level of a production plant. APM Studio gets data from different sensors and control devices contained in assets to optimize the performance, diagnose issues and eliminate unplanned downtime. But what is the field level? This is explained with the automation pyramid industry 4.0, which is crucial to understand manufacturing technologies.

The automation pyramid visualises the five different layers of automation by showing how technology can be integrated with devices in a production plant. Each level has its own infrastructure and performs different tasks.

At the bottom of the pyramid is the field level, where all the physical work and sensing happens. This level includes the measuring instruments (e.g. flow meters and level gauges) that provide input data of the different variables such as flow, pressure and temperature of product flow and assets. Elements like variable speed drives and actuators that move devices such as pumps or valves to keep control of the different variables are also included at the bottom layer of the pyramid.

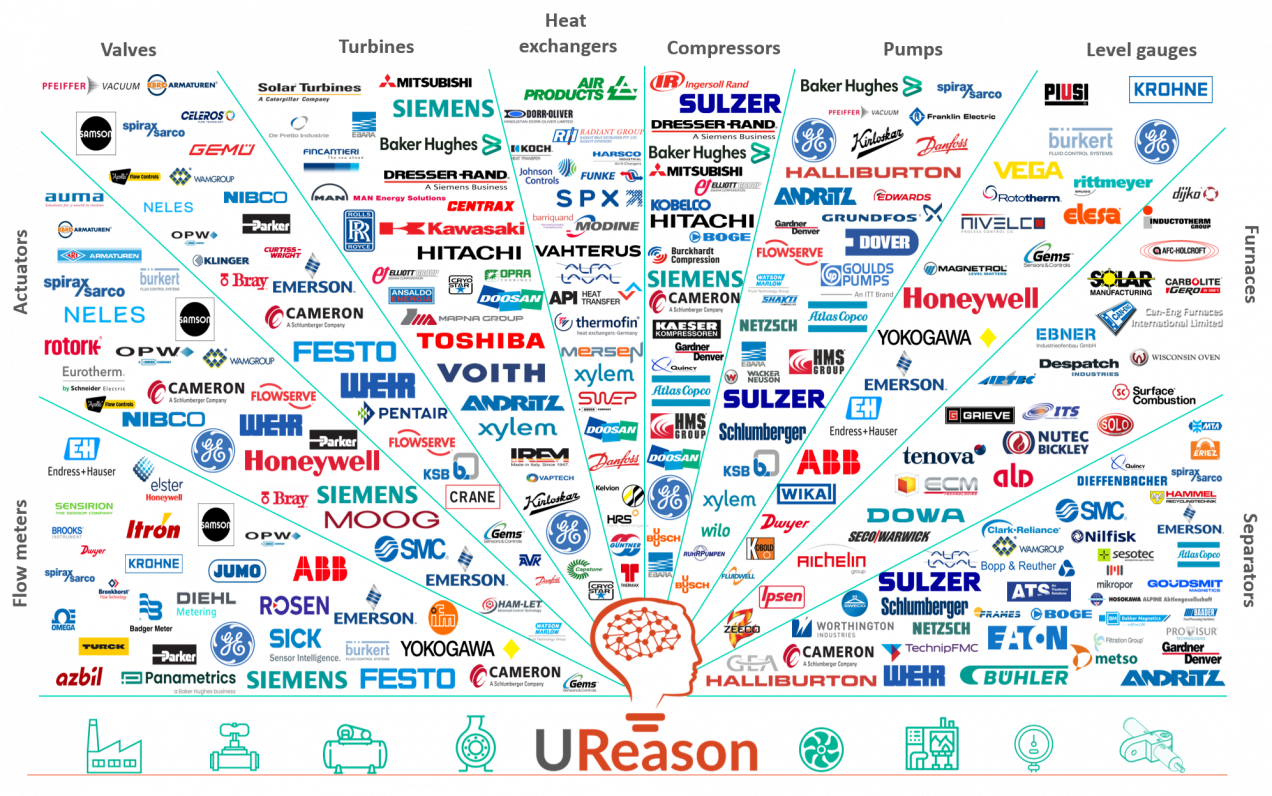

Common assets in the production plant that need to be monitored with measuring and control instruments include compressors, heat exchangers, furnaces, turbines, and separators.

There is a great variety of manufacturers that produce measuring and control instruments or assets that do the physical work in a factory. Check out this infographic, featuring the leading manufacturers of the devices that can be found at the field level.

Learn more about APM studio

Download our e-book to learn what UReason can do for you, find the unique functionalities of our next-gen APM software, look at the big data analytics framework and learn the different asset analysis models.