How to Make a Solid Business Case for Predictive Maintenance

A firm business case is the key to implementing PdM. What is a business case in the first place? By definition a business case is an explanation or set of reasons describing how a business decision will improve a business, product, etc., and how it will affect costs and profits and attract investments. Having a clear idea on the return on investment (ROI) of predictive maintenance helps to convince the relevant project stakeholders who have the decision power. Benefits of predictive maintenance include:

- Avoiding unplanned downtime

- Improving production uptime

- Reducing maintenance costs

- Increasing staff productivity

- Reducing liabilities

- Improving product quality

Building a business case is both a financial and strategic task. Fully understanding how the decision to move towards PdM affects and improves the organization is critical. Below are some strategic, analytical steps and questions that can help you to determine how PdM can align with the value drivers that are important for your organization and reduce operational risk:

- Map out the value drivers for the organization – Understand why there is the need to implement predictive maintenance technology. Value drivers for PdM could be, for example, risk reduction, reduction of unplanned maintenance, uptime improvement of assets and production, reducing maintenance costs etcetera.

- Criticality analysis – What are the biggest risks? Which critical equipment causes bottlenecks and has the highest cost when in downtime? Having those process-critical systems with enough preventable downtime mapped out will already provide a good base for a solid business case.

- Strategy fit – Is implementing PdM completely necessary? Could you get by with just condition-based monitoring? Are you able to adapt processes to the insights from the data? It is important to understand how PdM strategically fits together with other maintenance strategies and how it supports operational processes – the organization needs to be able to act upon these insights logistically to provide real, tangible value.

- Check the available data – What data is available from the systems for that critical asset group? Do you have enough historical failure data? Is it possible to build predictive models based on that data?

Now that you have gone through the strategic questions and gained the understanding how predictive maintenance can help your organization, it is time to move forward to the business case calculations.

Initial Investments for PDM

From a financial perspective, one of the biggest challenges to implementing predictive maintenance is potentially high initial investment costs. PdM implementation is easier with organizations that have a strong existing Operational Technology (OT) infrastructure (OT “backbone”). This is not always the case and making the initial investment towards the necessary equipment and operational capabilities can be considerably high. These initial costs may include:

- Implementing sensors to gather (streaming) data from your assets (although new machinery can come with already built-in sensors)

- Utilizing data collection systems to synchronize (real-time) data collection from the sensors and data storage for further analysis on asset’s remaining lifecycle

- In some instances, there is a need for data re-structuring from process historians

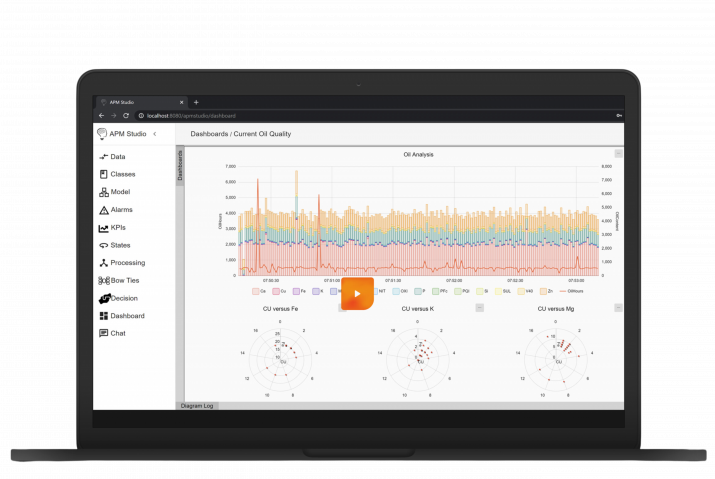

- Deployment of predictive analytic platforms

- Customization costs regarding specific characteristics of the operational processes

It is important to mention that relevant operational personnel must be educated about predictive maintenance and its processes for better adoption. This requires additional time, energy and resources. Therefore, it is important to evaluate the level of existing OT infrastructure, personnel capabilities and seriously consider further investments towards this proactive maintenance strategy.

Calculations for the Business Case

The traditional return on investment (ROI) calculation formula looks like this:

We cannot see the future, but we can use estimates, historical data and expertise from the industry on predictive maintenance to get an understanding about the potential return on investment. For example, making use of in-house expertise is of utmost value; we have experience on asset failure based on historical events recorded in our systems as well as what the financial impact was, in terms of repair costs, downtime, labor costs etc.

Based on that evidence/data we can get a better estimation on how much implementing predictive maintenance strategy could reduce these costs since we could “see” the failure earlier and plan maintenance only when needed.

We will go through building a business case step-by-step. More detailed template for predictive maintenance calculations can be found HERE. Below are the calculation steps to follow with an example in the end:

1. Calculate the initial project implementation costs

- Initiation – drawing up of specifications, project plan, marketing research

- Engineering and development – solution basic design, detailed design, development costs

- Purchase and installation – cost of hardware & software, spare parts, placing and connecting sensors, connectors, cables, control box et cetera

- Implementation in organization – setting up governance, procedures, training of personnel, setting up PdM plans, construction of other documentation et cetera

2. Calculate the cost reduction

- Reduced downtime of your assets – less machine failures and optimized repairs result in less costs on maintenance

- Reduction of unplanned repairs – means more stable production and operations, decreasing costs occurred from lost production

- Reduction of spare parts used – since PdM enables to replace parts when actually needed (not when the calendar says so), the amount of spare parts used (and in storage) can be reduced

- Reduced maintenance labor cost – Since PdM allows maintenance personnel to focus on the machines that actually need it, unnecessary labor costs can be reduced

- Reduction of replacement costs – ordering and replacing machinery/component can be expensive and time consuming, PdM can prevent machines from reaching failure

- Reduction of “over-investments” – keeping a good balance between CAPEX capital expenses for additional money machines that have to be bought to compensate for a non-availability and OPEX of the maintenance organization

3. Calculate revenue increase

- Increased equipment availability – increased production and operational efficiency

- Increased or accelerated production/sales – more asset uptime means more production resulting in more potential sales

- Increased product quality – less faulty products and the need for re-works, less waste in materials and production time resulting in increased profitability

- Increased energy efficiency – Wear&Tear can cause machinery to consume more energy than they optimally should. Machinery in good condition will use less energy, reducing overhead costs.

4. Allocate “weights” to the intangibles

- Effect on organization – how PdM improves the overall efficiency of the organization

- Operational process improvement – how the operational processes improve

- Risk reduction – how PdM helps to build a safe working environment for your personnel

This brings us to more elaborated formula for calculating ROI:

Below is a hypothetical example showing how all this comes together:

For illustration purposes, we will go through a hypothetical predictive maintenance project.

First, we will lay down the cost saving and/or income from this project to understand the benefits in financial terms.

As a second step, we will calculate one-off costs for the project. These go from costs to initialize the project, designing the solution, installation to transfer to the organization.

Thirdly, it is important to understand what the recurring costs over the years are and if there are any additional costs regarding labor costs.

Lastly, we want to evaluate the profitability of the project to make the GO/NO-GO decision. Taking into consideration the payback period, what is the yearly ROI etcetera.

There is a notion that I can outline to aid the process of building a business case:

– Provide the range for business case calculations

In case the outcomes of the business calculation have some risk, we advise you to use ranges. Depending on your risk attitude you could either use averages of the ranges or the minimum outcome of the ranges in calculating the total return.

This article provides you with tools and insights needed to build a business case for a predictive maintenance project. It is essential to understand what the strategic value drivers for maintenance are and undergoing with criticality analysis to understand which equipment is costing the organization the most. Following the outlined steps to build a business case will support you in making the decision to go forward with a predictive maintenance project or not by providing an initial overview of the return on investment and putting more detailed numbers on paper.

Download the ROI Calculator Template

Simplify the process with our Predictive Maintenance ROI calculator. Get yours now by filling in the form.