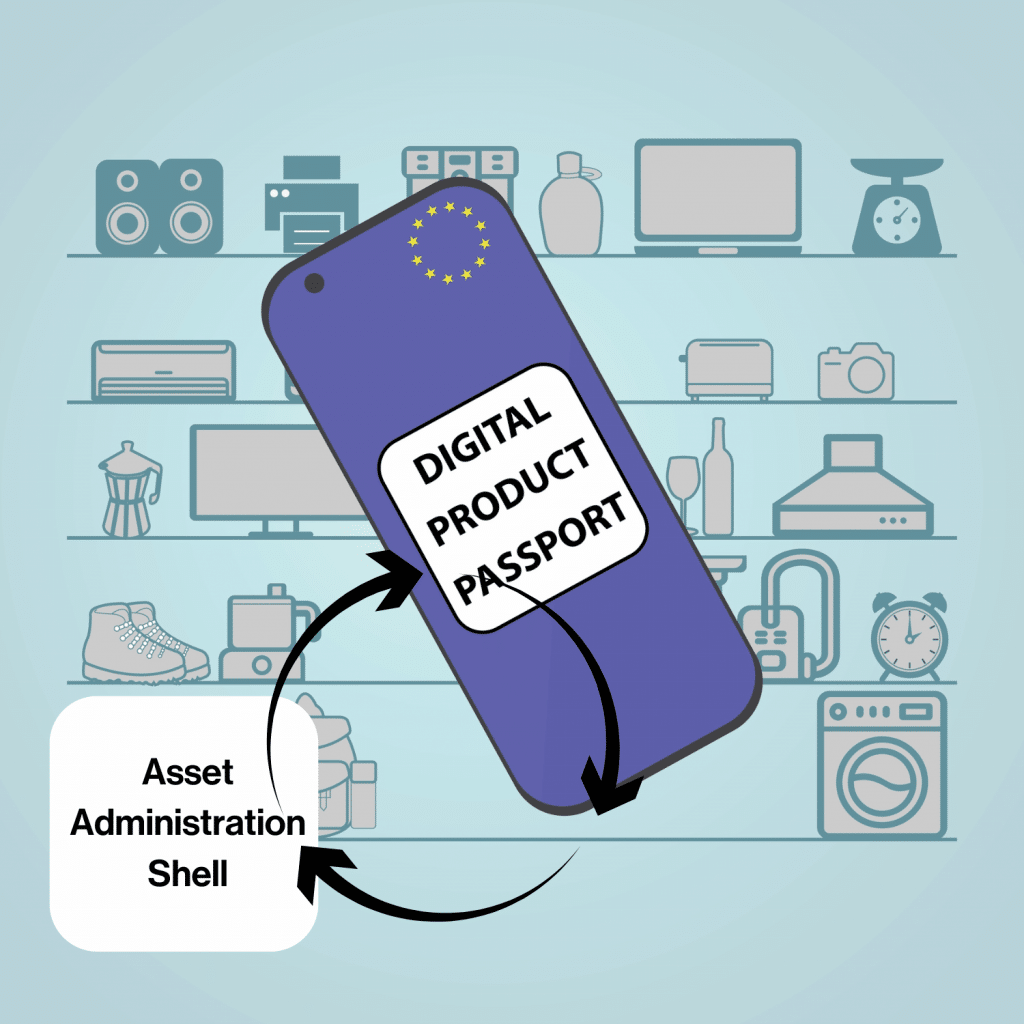

As the world moves towards a more sustainable and digitally interconnected future, the European Union’s upcoming Digital Product Passport (DPP) legislation, set to be enforced starting from 2025, marks a significant step forward. This legislation mandates that almost all products sold within the EU must have a digital passport, containing detailed information about their lifecycle, environmental impact, and sustainability. Simultaneously, the adoption of the Asset Administration Shell (AAS) standard, as defined by IEC 63278-1:2023 , is set to transform how industrial assets are managed and integrated. Together, these innovations promise to revolutionise industry practices, enhance transparency, and drive sustainability.

As the world moves towards a more sustainable and digitally interconnected future, the European Union’s upcoming Digital Product Passport (DPP) legislation, set to be enforced starting from 2025, marks a significant step forward. This legislation mandates that almost all products sold within the EU must have a digital passport, containing detailed information about their lifecycle, environmental impact, and sustainability. Simultaneously, the adoption of the Asset Administration Shell (AAS) standard, as defined by IEC 63278-1:2023 , is set to transform how industrial assets are managed and integrated. Together, these innovations promise to revolutionise industry practices, enhance transparency, and drive sustainability.

Digital Product Passport (DPP): Enhancing Transparency and Sustainability

The Digital Product Passport (DPP) aims to provide comprehensive, easily accessible information about products. It will include details on the product’s durability, repairability, recycled content, and carbon footprint, among other attributes. By scanning a data carrier, consumers and businesses can access this information, facilitating informed purchasing decisions, efficient recycling, and better lifecycle management. The DPP supports the EU’s broader goals under the Ecodesign for Sustainable Products Regulation (ESPR), which seeks to improve product circularity and reduce environmental impact.

Asset Administration Shell (AAS): Standardising Digital Representation

The Industrial Digital Twin Association (IDTA) is working on the development and implementation of the Asset Administration Shell (AAS), a key element in the digital transformation of industries under the Industry 4.0 framework. The AAS acts as a digital twin for physical assets, containing all relevant data and functionalities in a standardised digital format. This enables different systems and devices within industrial settings to communicate and share information seamlessly.

IDTA’s focus is on creating a standard that is easy to implement across various industries, ensuring that the AAS can be widely adopted. By standardising the way asset data is managed and accessed, the AAS helps to improve operational efficiency, reduce downtime, and optimise processes within manufacturing environments. The association works closely with industry partners to continually refine the AAS, making sure it stays relevant and effective as digitalisation progresses.

Synergy Between DPP and AAS: Transforming Industry Practices

The integration of DPP and AAS represents a significant advancement in industrial asset management and product transparency. Here’s how they collectively transform the industry:

-

Enhanced Data Management and Interoperability

– Unified Data Access: With AAS providing a standardised digital framework, all relevant product and asset data can be uniformly accessed and managed within the DPP structure. This ensures that data from various sources is harmonised, enhancing interoperability across platforms and systems.

– Streamlined Information Flow: The AAS enables seamless data exchange between different applications and devices, reducing silos and ensuring that all stakeholders have access to consistent, up-to-date information. -

Improved Lifecycle Management and Sustainability

– Comprehensive Lifecycle Tracking: The DPP, enriched with AAS data, offers detailed insights into the entire lifecycle of products and assets, from production to end-of-life. This comprehensive visibility supports better decision-making and optimises maintenance and recycling processes.

– Sustainability Metrics: Companies can leverage the detailed environmental data provided by the DPP and AAS to enhance their sustainability initiatives, monitor carbon footprints, and comply with regulatory requirements. -

Regulatory Compliance and Reporting

– Automated Compliance: The integration of DPP and AAS simplifies compliance with EU regulations by automating the collection and reporting of required data. This reduces administrative burdens and ensures that companies consistently meet legislative standards.

– Enhanced Transparency: By providing transparent, easily accessible product and asset information, companies can build trust with consumers and stakeholders, demonstrating their commitment to sustainability and regulatory compliance. -

Digital Twins and Predictive Maintenance

– Creation of Digital Twins: The AAS facilitates the creation of accurate digital twins, which can be integrated into DPPs to provide real-time monitoring and simulation capabilities. This enables predictive maintenance and optimises asset performance, reducing downtime and operational costs.

– Simulation and Optimisation: Companies can use digital twins to simulate different operational scenarios, optimise maintenance schedules, and improve overall equipment effectiveness.

Preparing for the New Legislation

To fully capitalise on the benefits of DPP and AAS, companies must take proactive steps to integrate these standards into their operations:

-

Adopt Standardised Frameworks

– Implement the AAS standard across all assets to ensure uniform data representation and interoperability.

– Align product data with DPP requirements, ensuring comprehensive and accurate information is available. -

Invest in Digital Infrastructure

– Develop or enhance digital platforms capable of managing and integrating DPP and AAS data.

– Leverage advanced technologies such as AI and machine learning to automate data processing and generate actionable insights. -

Educate and Train Stakeholders

– Provide training to employees and stakeholders on the benefits and usage of DPP and AAS.

– Promote a culture of transparency and sustainability within the organisation. -

Collaborate with Industry Partners

– Engage with industry consortia and standardisation bodies to stay updated on best practices and regulatory developments.

– Partner with technology providers to ensure seamless integration of DPP and AAS into existing systems.

Conclusion

The convergence of Digital Product Passports and Asset Administration Shells brings a new era of transparency, sustainability, and efficiency in the industrial sector. Companies can enhance their regulatory compliance, optimise asset management, and contribute to a more sustainable future by preparing for the upcoming legislation and integrating these standards into their operations. Embracing these innovations will not only ensure compliance with EU regulations but also position companies at the forefront of the digital transformation in industry.