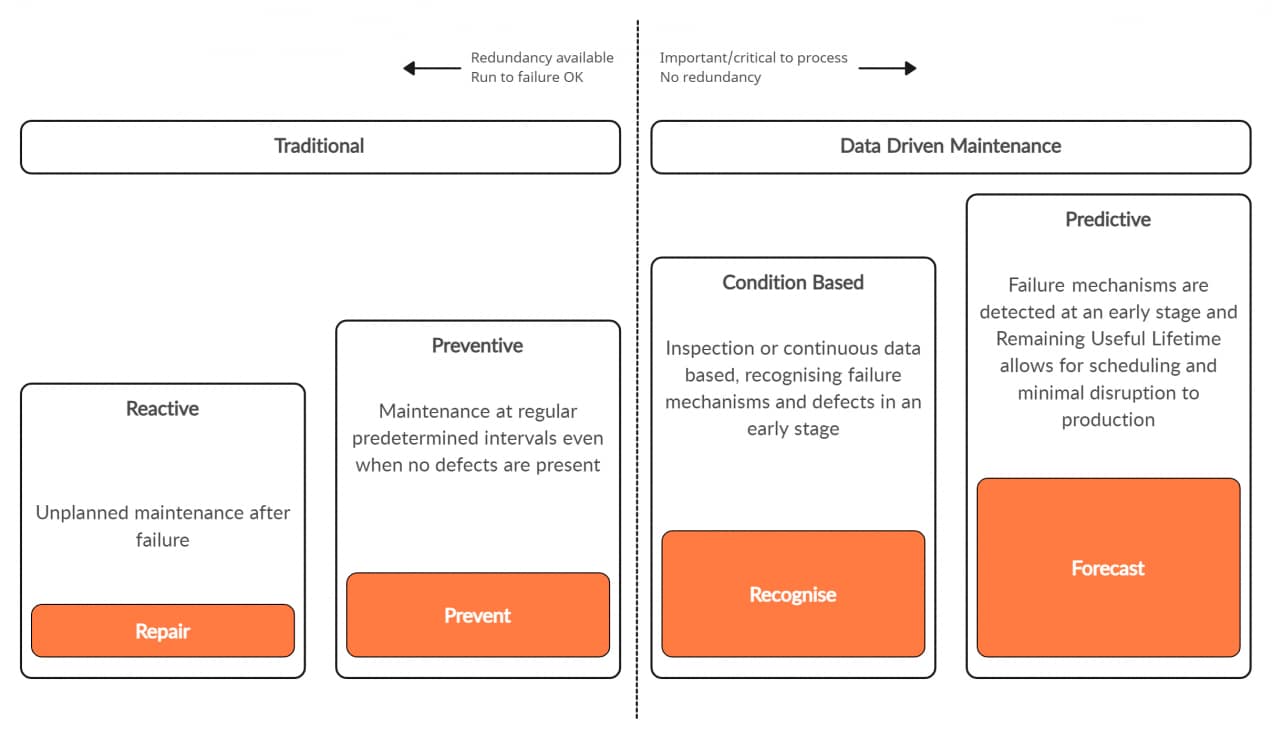

Data-driven maintenance refers to the use of data analysis techniques to guide maintenance activities. This approach shifts maintenance from a reactive or scheduled process to a predictive one, where actions are based on data insights rather than on predetermined intervals or reactive maintenance after a failure has occurred.

Data driven maintenance uses data science, machine learning, and depending on the case the additional sensors to monitor and analyze equipment performance in real-time.

We have all seen this infographic in various forms, guiding organisations to different maintenance models and strategies. Now predictive is not perse better than reactive maintenance. It all depends on the value your asset has to the process it supports, and in case you have redundancy a reactive scheme may just be fine, or when sufficient time is available to fix the failure and the risk of the failing asset is acceptable.

But note that data-driven maintenance is not just about the data. For organisations to shift from preventive/reactive maintenance strategies to condition based and predictive strategies there are also very often organizational changes needed.

Check Out More of Our Articles

If you enjoyed reading this article make sure to check out more articles on our website!