Sharing data in the industry can offer numerous benefits, fostering collaboration, innovation, and efficiency. In our domain, of Asset Performance Management software solutions, the sharing of data is always a topic that is addressed early on in any project or onboarding of a customer on our SaaS solutions. Often it is addressed just with an NDA (Non-Disclosure-Agreement) but more and more often end-users see the benefits of sharing anonymized data with others.

Some of the key reasons we see why organizations choose to share data:

Innovation: Sharing data allows organizations to combine their resources and expertise to drive innovation. By pooling data from various sources, businesses can gain new insights, identify issues, improve products, and develop innovative products, services, and solutions. The OEMs of your assets would love to tap into the wealth of operational data you have but you can also benefit from operational data of other operators!

Efficiency and Cost Reduction: Data sharing can lead to increased efficiency and cost reduction by avoiding duplication of efforts and resources. For example, in maintenance services, sharing data among your maintenance service partners can streamline processes, reduce inventory costs, and improve uptime and planning.

Improved Decision-Making: Access to a broader range of data enables organizations, in the APM domain, to make more informed and data-driven decisions. By sharing data internally or with external partners, businesses can improve operational usage and performance, leading to more effective decision-making.

Enhanced Collaboration: Data sharing facilitates collaboration among different departments within an organization or between different organizations. By sharing data across departments or with external partners, businesses can break down silos, foster cross-functional collaboration, and achieve common goals more effectively. We experience this frequently with our Control Valve App, it provides detailed analytics and insights for process control as well as maintenance which are often in different silos at our customers.

Risk Mitigation and Compliance: Sharing data can help organizations mitigate risks and ensure compliance with regulations and industry standards. For example, in the manufacturing sector, sharing data for risk management purposes allows institutions to identify and address potential risks more effectively (see OREDA for example).

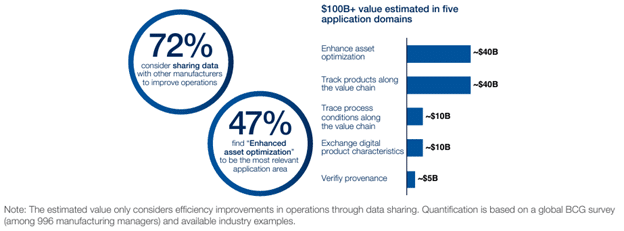

The reasons to share data, and the value you gain, is further emphasized in the 2020 white paper by the World Economic Forum in collaboration with the Boston Consulting Group: “Share to Gain: Unlocking Data Value in Manufacturing”. The white paper identifies five main areas of data sharing in manufacturing that provide value:

- Enhancing asset optimization;

- Tracking products along the value chain;

- Tracing process conditions along the value chain;

- Exchanging digital product characteristics; and

- Verifying provenance.

A staggering 47% of the respondents found “Enhancing asset optimization” to be the most relevant application area.

Enhancing asset optimization was defined as combining data from multiple users of the same type of machinery allowing manufacturers to improve algorithms that, for example, enable predictive maintenance. Sharing data can thus optimize asset performance by increasing machine uptime and product quality, creating a win-win situation for all stakeholders. This is particularly important for manufacturers who lack the amount of data needed to fuel robust analytics algorithms. Coupled with the value estimated in this application area of 40 billion $ a no-brainer to invest in. Yet, as also addressed by Commission President Ursula von der Leyen in the State of the Union in 2020 “the reality is that 80% of industrial data is still collected and never used. This is pure waste.”. Trust, knowledge and technical barriers prevent this (more on this later!).