Pneumatic actuators are commonly used in industrial processes to control the movement of valves, dampers, and other mechanical components. These actuators rely on compressed air or gas to generate motion and perform their functions. Like any mechanical component, pneumatic actuators can experience various failure modes. Here are some common pneumatic actuator failure modes:

1. Loss of Air Supply

A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position.

2. Air Leakage

Air leaks can occur in the actuator’s pneumatic system, leading to a gradual loss of pressure and reduced actuator performance. Common areas for leaks include seals, O-rings, and pneumatic connections.

3. Sticking or Binding

The actuator’s internal components, such as the piston or seals, may become stuck or bind due to debris, corrosion, or improper lubrication. This can prevent the actuator from moving smoothly or at all.

4. Slow Response

If the actuator is slow to respond to control signals, it can result in poor process control and potentially compromise the safety and efficiency of the system.

5. Excessive Wear

Components within the actuator, such as the piston and cylinder walls, can wear over time, affecting the actuator’s performance and longevity.

6. Cylinder Damage

Damage to the actuator’s cylinder, such as dents or scoring, can impair its ability to function properly.

7. Valve Positioning Errors

Pneumatic actuators are often used to control valves. Errors in valve positioning can occur due to actuator failures, leading to improper flow control.

8. Corrosion

Corrosion of internal components or the actuator’s exterior surfaces can occur in corrosive environments, leading to performance degradation and potential failure.

9. Seal Failure

The seals in the actuator can deteriorate or fail over time, resulting in air leaks, loss of pressure, and reduced actuator effectiveness.

10. Freezing

In cold environments, moisture in the compressed air can freeze within the actuator, causing it to malfunction or become stuck.

11. Improper Lubrication

Inadequate lubrication of moving parts can lead to increased friction, wear, and reduced actuator lifespan.

12. Over pressurization

Applying excessive air pressure to the actuator can cause damage or failure, including rupture of internal components.

13. Electrical or Control System Issues

Pneumatic actuators often incorporate electrical components for position sensing or control. Failures in these electrical components or control systems can lead to actuator malfunctions.

To prevent and address pneumatic actuator failure modes, regular inspection, maintenance, and lubrication is essential. Additionally, monitoring air pressure and quality in the pneumatic system can help identify issues early. Proper training and safety procedures for personnel working with pneumatic actuators can also contribute to their reliable operation.

Up Next: Failure Modes of Electric Actuators

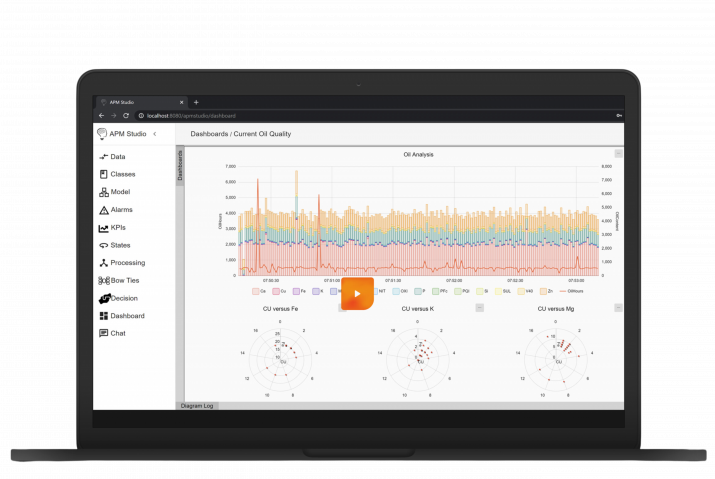

Get Full Access to Expert FMEA Insights

A structured approach to analyzing risks and ensuring better valve performance.