Keeping steam turbines and their subsystems running smoothly is no small task. With so many moving elements—lube oil systems, gears, generators—any unexpected failure can disrupt production, jeopardize safety, and drive up costs. At UReason, we’ve built our in-house software called APM Studio to give you immediate insight into your operations and alert you to potential problems before they escalate. Our interactive Storylane demo showcases how it all works and lets you click through each step to see APM Studio in action.

Instant Visibility into Potential Issues

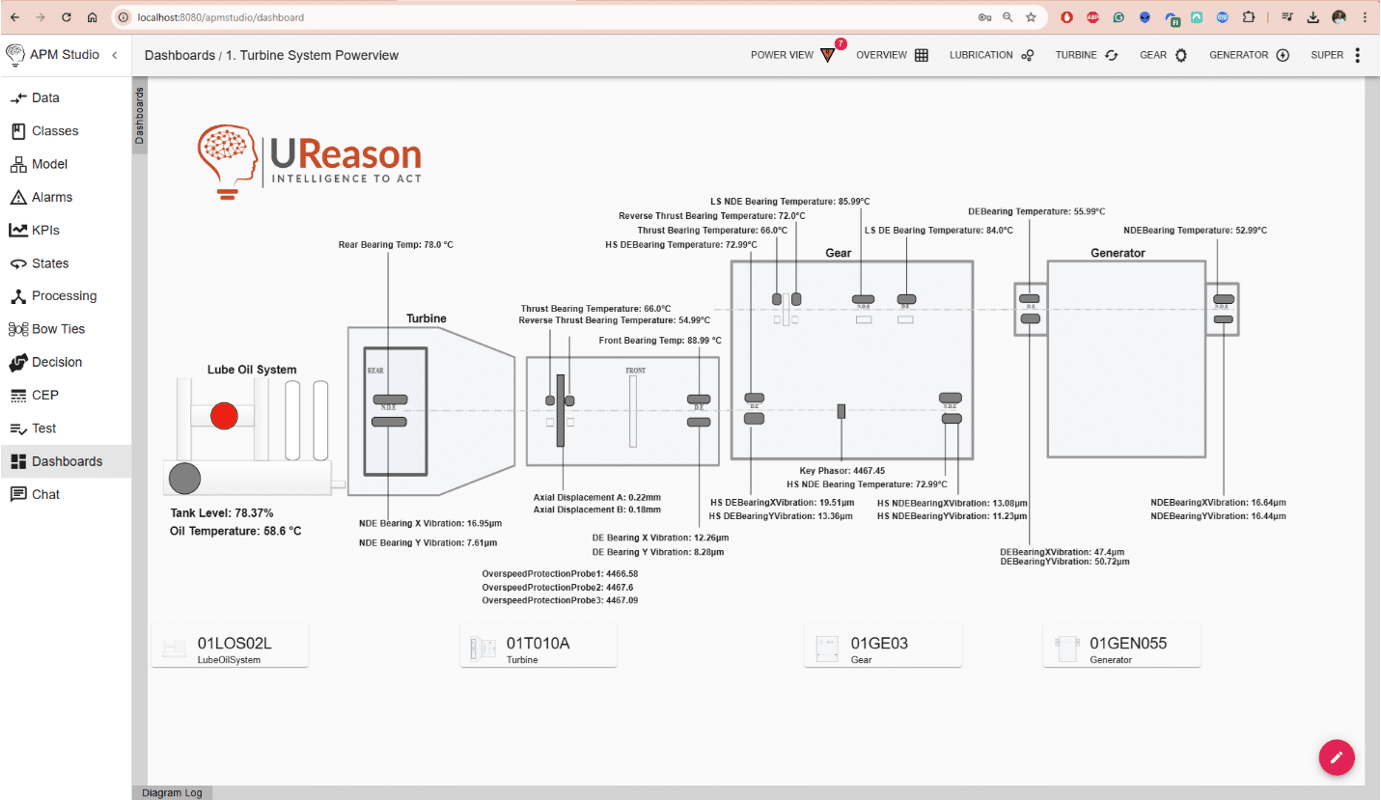

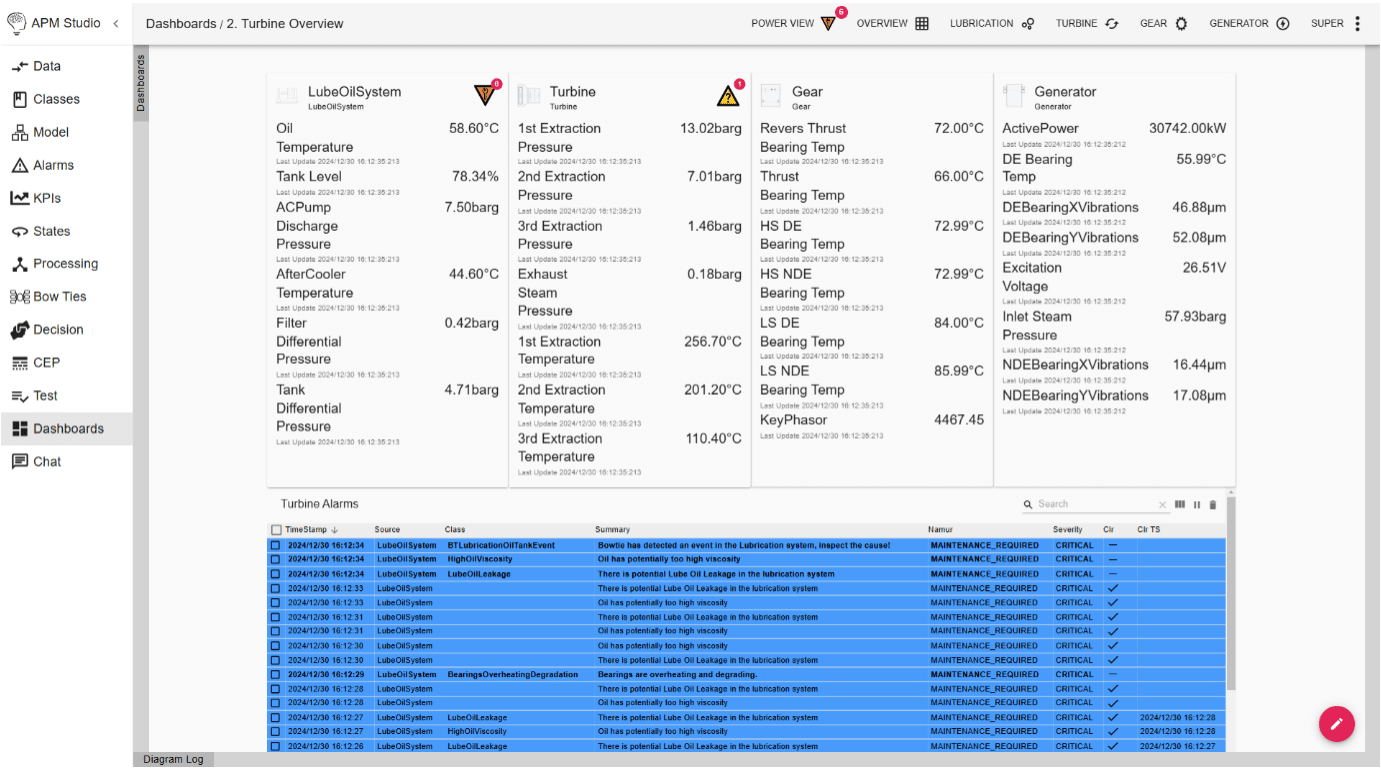

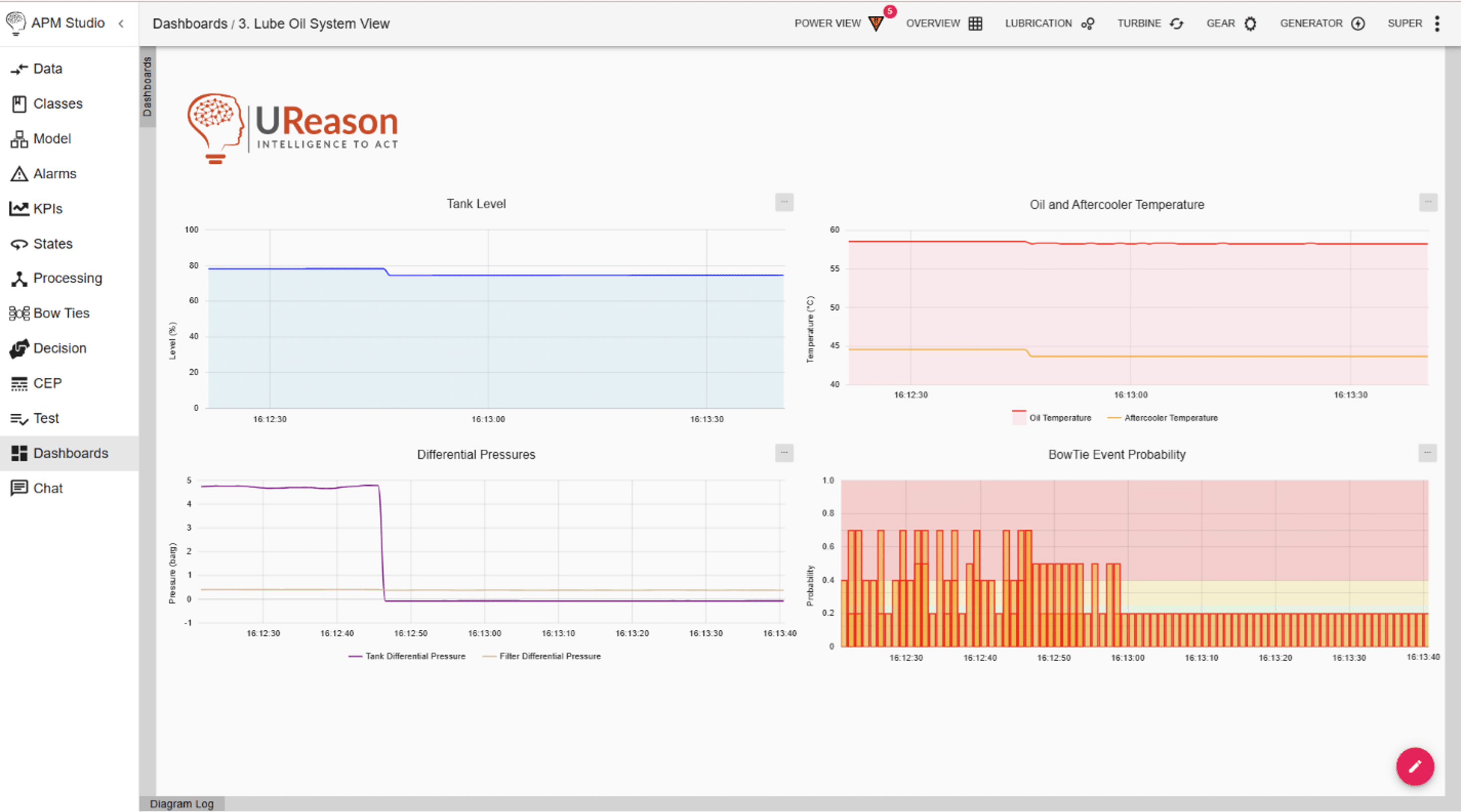

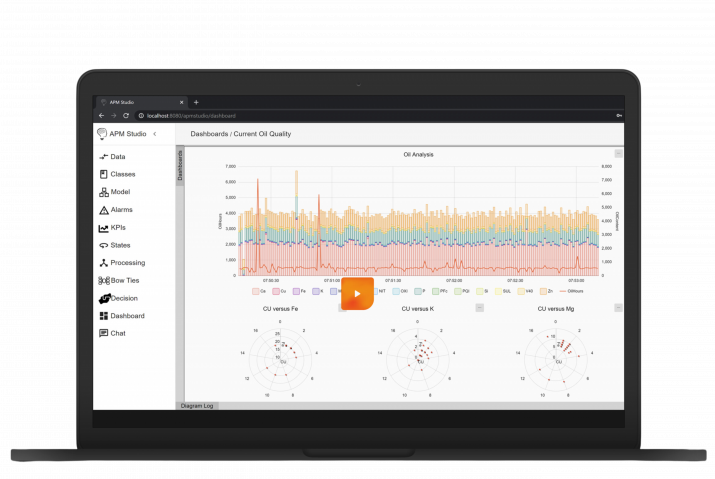

From the moment you open the main dashboard, APM Studio provides a high-level view of your turbine system’s health. Each subsystem has its own status indicator—green for normal operation, red for any active issues. Clicking on the subsystem card takes you to a detailed perspective where you can see real-time data trends, active alarms, and relevant KPIs. This means you can instantly zero in on areas that need attention, saving valuable time when troubleshooting.

Predictive Analytics and Soft Sensors

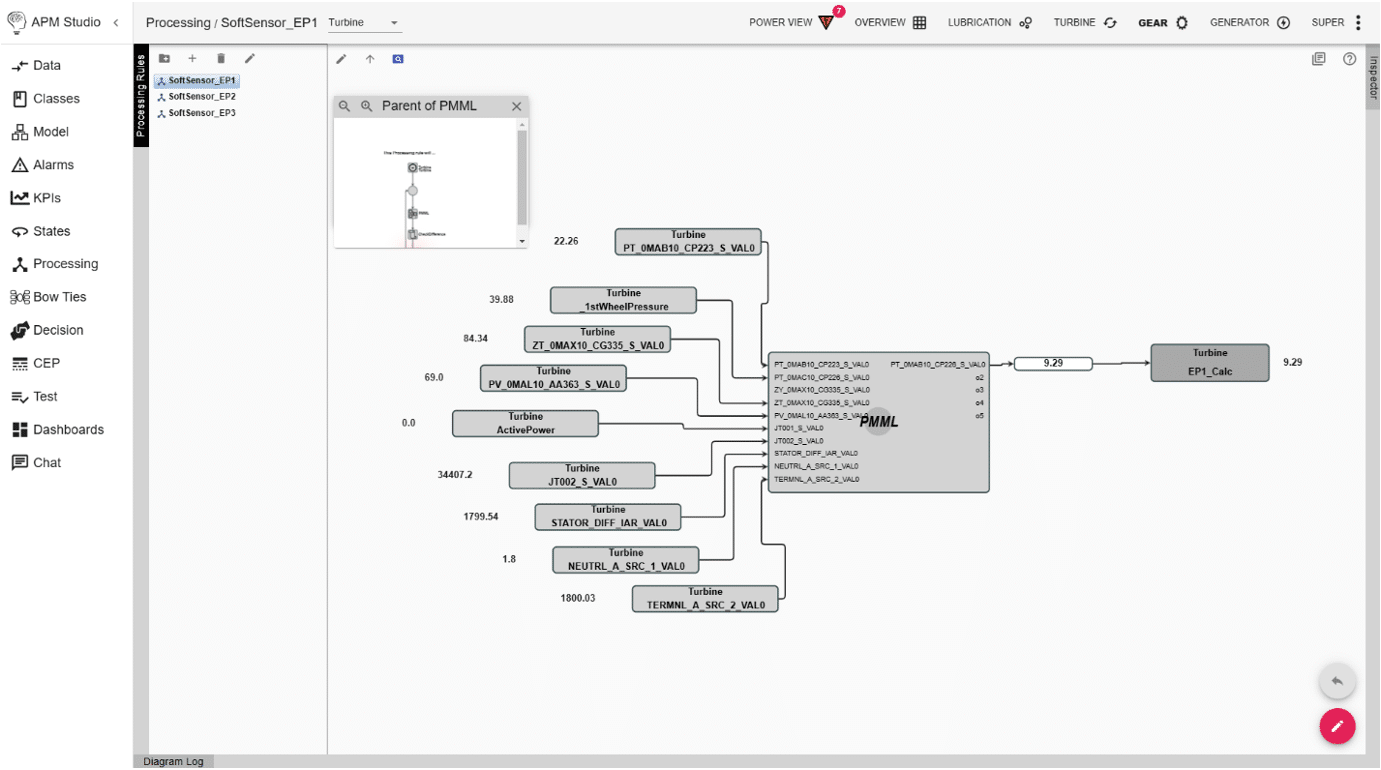

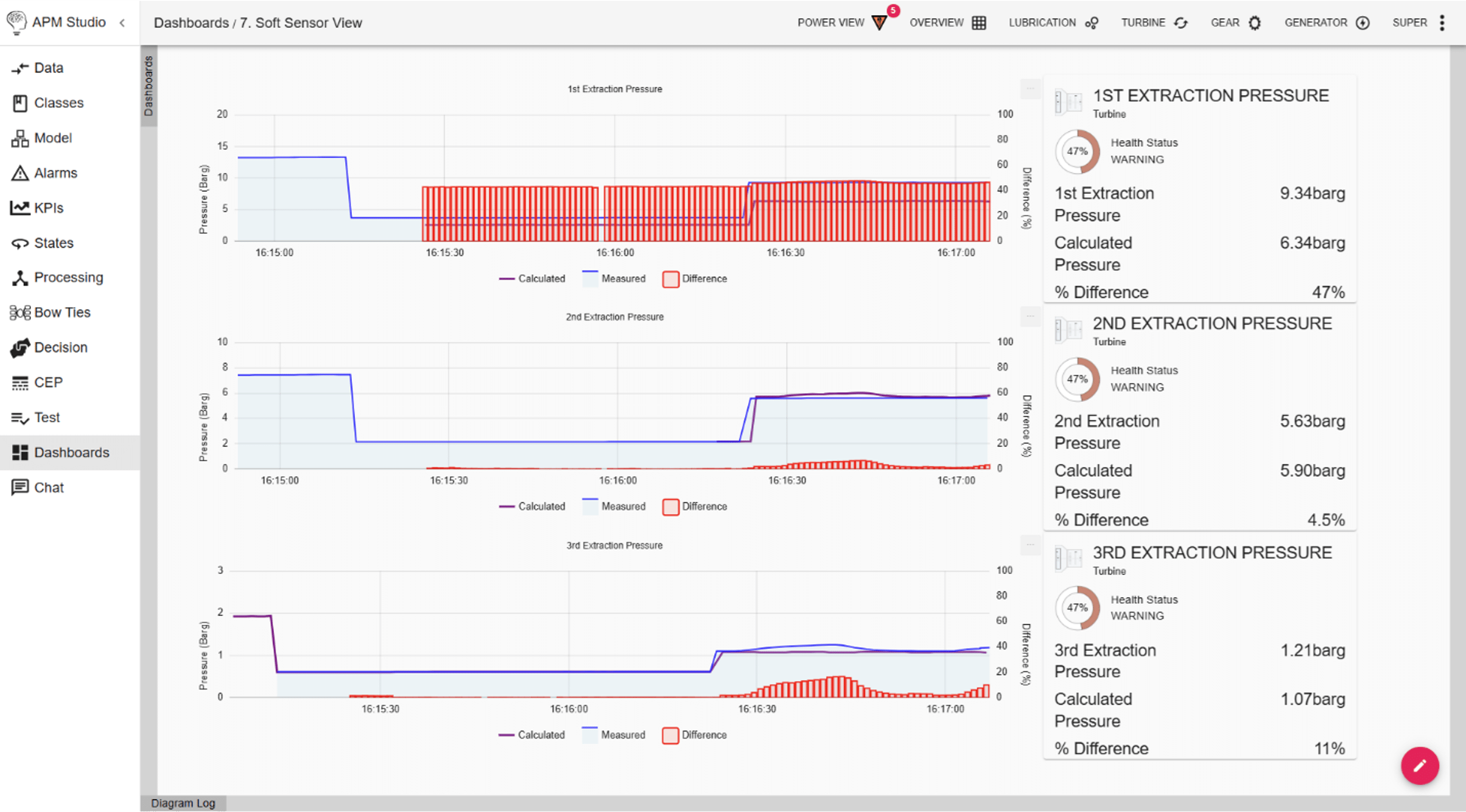

A standout feature in APM Studio is the capability to deploy Soft Sensors on real-time data, which leverages machine learning to predict certain values—like turbine extraction pressures—without installing extra physical sensors. If these predicted values deviate significantly from actual measurements, the system recognizes abnormal conditions and raises an alert. The best part? Soft Sensors are configured through Processing Rules and PMML (Predictive Model Markup Language) or Python, using a visual, drag-and-drop interface instead of complex scripting. This makes it easy for both data experts and operational teams to collaborate on machine learning initiatives.

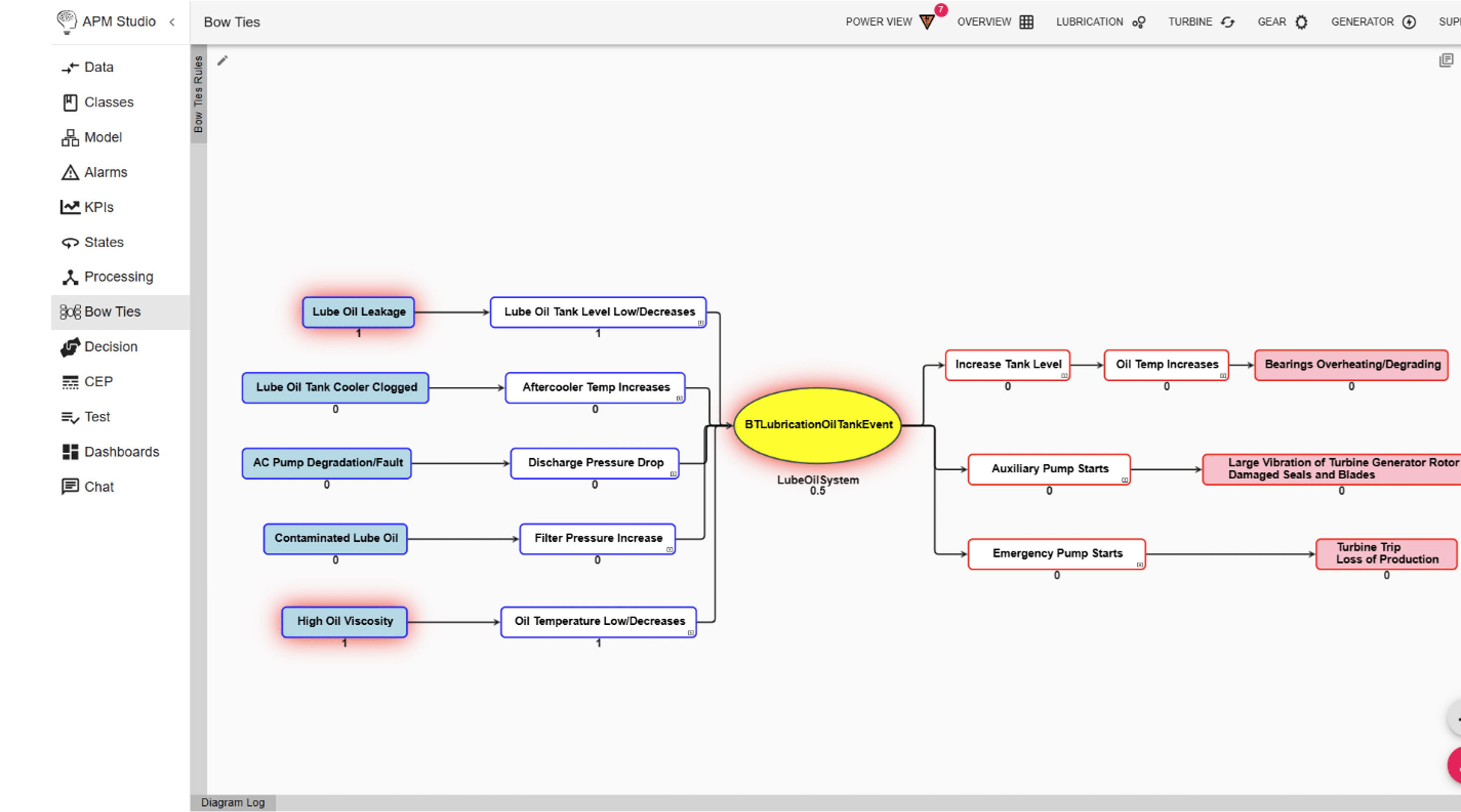

Smart Alarm Management with BowTie Modelling

Alarm overload is a common challenge in industrial settings, but APM Studio streamlines your alerts with customizable definitions, advanced logic, and a user-friendly browser for viewing alarm history. With BowTie models, APM Studio goes a step further by analyzing the causes and consequences of an unwanted event. The BowTie visualization helps you pinpoint root causes, understand risk probabilities, and plan mitigation strategies. As you click through the demo, you’ll see how BowTies transform scattered data points into a cohesive cause-and-effect roadmap.

Seamless Data Connectivity

One major obstacle to effective monitoring is inconsistent data from various sources. APM Studio eliminates this friction by integrating with popular protocols such as OPC UA, Modbus, AVEVA CONNECT, OI4, and SQL databases. Within the demo, you’ll see how simple it is to map incoming signals from your turbine directly to digital twins, known as “instances of Classes” in APM Studio. This modular approach also makes it easier to replicate configurations for additional assets and scale up your monitoring efforts without reinventing the wheel.

Ready to Explore Our Demo?

If you’re looking for a proactive approach to asset performance and reliability, check out our Storylane demo, which is a great place to start. Experience firsthand how APM Studio’s dashboards, predictive analytics, and advanced alarm management come together in a single, user-friendly platform. Click through each step to see how maintenance teams can spot issues quickly, dive deeper with root-cause analysis, and make informed decisions to prevent downtime.

Learn More About APM Studio

Our product APM Studio is the leading Real-Time Analytics Software for Machines and Processes to make them Smarter.