What Is a Soft Sensor?

You may be wondering what is meant by the term “Soft sensor”? Perhaps it has something to do with the material qualities of the sensor? Maybe this type of sensor can only be mounted on soft materials? Definitely not. This article will provide you with an overview of what is meant by “Soft sensors” and how they can help monitor your critical process measurements.

The term “Soft sensor” can be strikingly new to some people. It might be a surprise that this term was already in use way back in the 1990s when, for example, Jules Oudmans, our Director Consultancy, implemented “Soft sensors” on refining processes where the measurement of the refined product quality was not available directly in the process. But what is a “Soft sensor”?

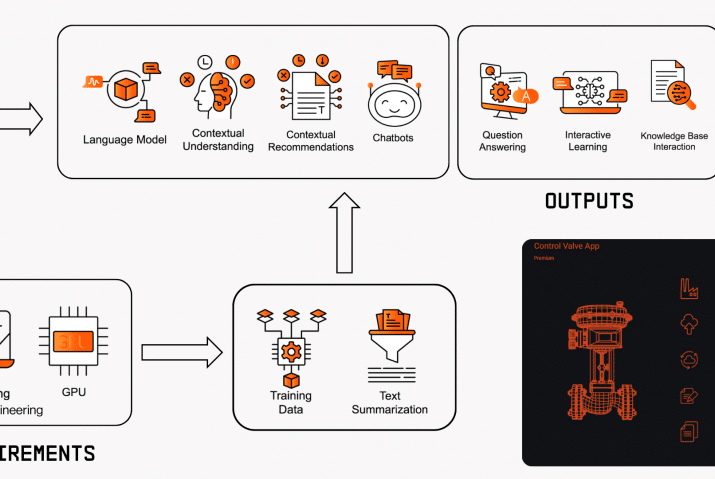

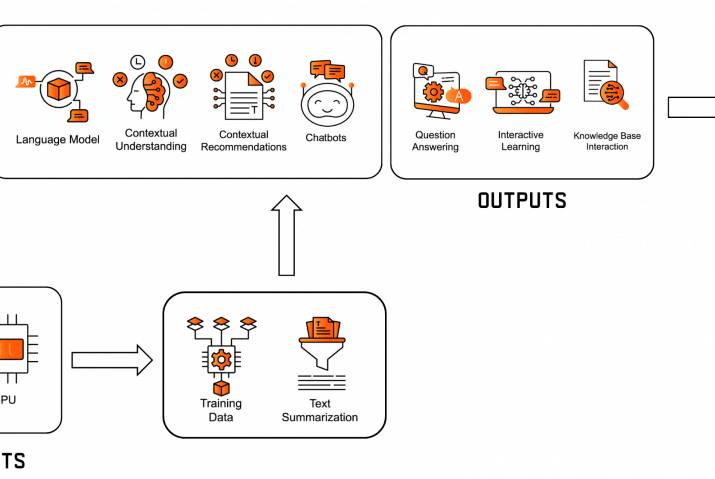

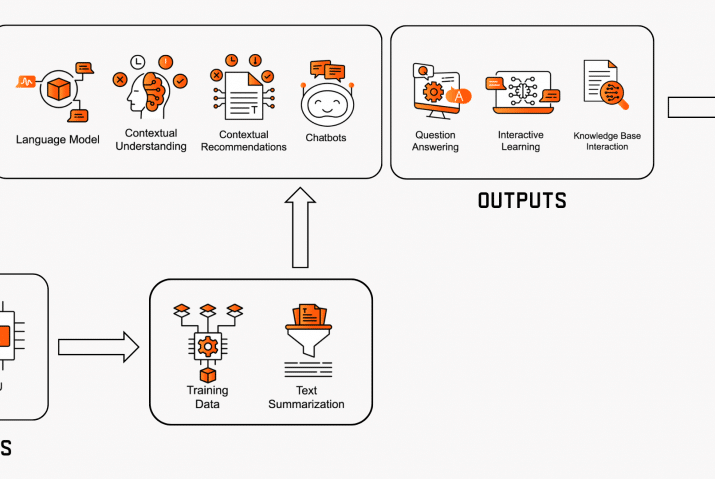

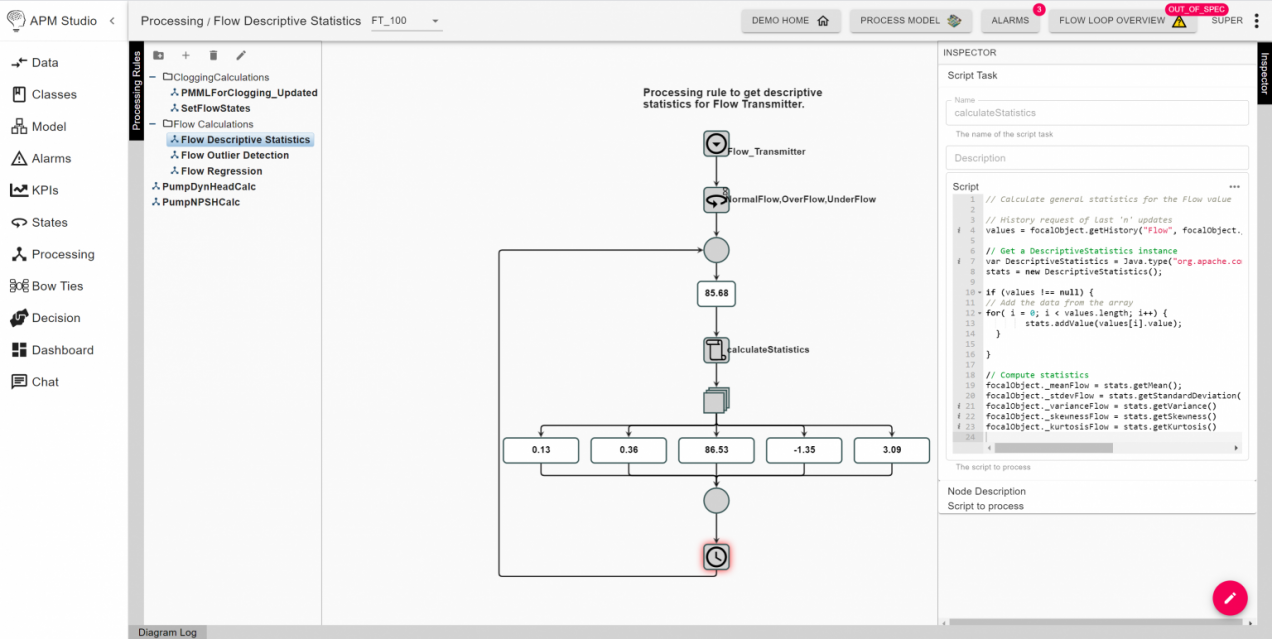

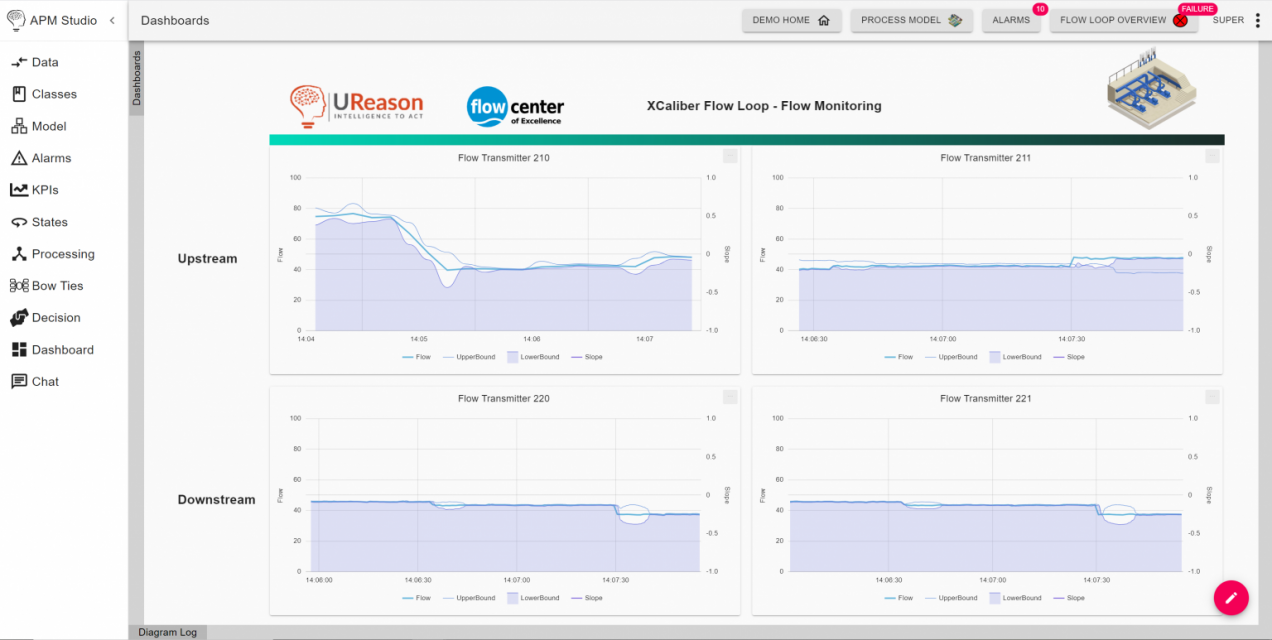

EY’s report on Smart sensors as drivers of Industry 4.0 gives the following definition: “Soft sensors are software-based models that can use algorithms to process hundreds of measurements simultaneously, and in doing so, predict parameters that cannot be measured directly. The results can be continuously updated and presented to a process operator.”

This definition needs a small extension: Soft sensors can also be used to monitor expected outputs of process measurements. The result of this is an identification of potential sensor degradation failure or process anomaly. You could call this a digital twin of a sensor.

The term “Soft” is an abbreviation of the word “Software” since the sensor signal models are usually implemented in computer programs. The term “sensor” in this context is used because these algorithms provide insights and information similar to better known hardware sensors. Basically, a Soft sensor creates a new or replacement (twin) signal based on the calculations made by embedded algorithms that are trained on historical data. This signal can be utilized to analyze, monitor, and control your industrial processes, just as you would use information from a traditional hardware sensor.

Benefits of Soft Sensors

Industrial plants and processes create vast amounts of data. The ability to gather and analyze this data in real-time has significant potential to expand the influence sensors have on monitoring, controlling and safe-guarding the processes.

Soft sensors have the ability to estimate real-time data, overcoming delays imposed by, for example, a slow manual process such as a quality check in a lab. This means faster insights and more control over the output of your processes. Combining traditional hardware sensors with Soft sensors enables you to improve the performance of control strategies and safeguard your processes. Additionally, Soft sensors, that derive unmeasured values, can be used in tough, hazardous environments where traditional hardware sensors are too expensive or can not be installed and implemented.

A Quick Recap on Soft Sensor Benefits:

- Allow prediction of measurements that cannot be measured directly

- Provide a back-up for hardware sensors that are critical for safe or efficient operations

- Can provide measurements in tough, hazardous environments where traditional hardware sensors cannot be installed or are too expensive to implement

Soft Sensors Monitoring Your Process Critical Measurements

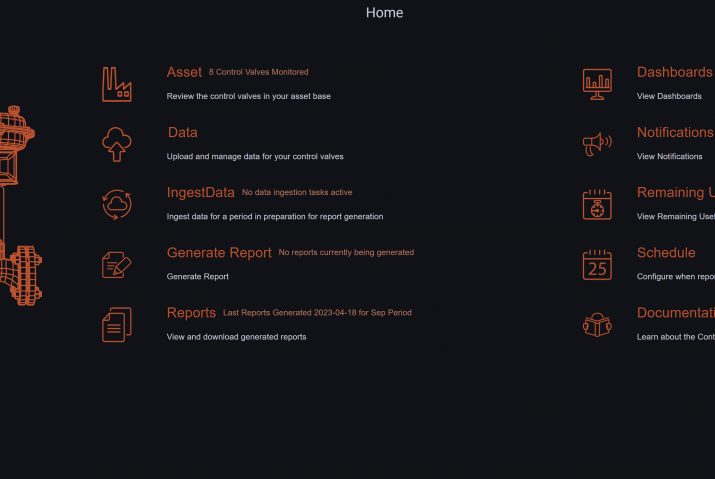

As mentioned previously in this article, Soft sensors enable you to predict measurements that cannot be measured directly. This is a fundamental building block for smart factories. Reliability strategies where Soft sensor techniques are implemented allow estimation of future asset and process behaviour, using available real-time data and relevant (mathematical) algorithms, when the hardware sensor is malfunctioning and not generating data. This increases the control over your critical processes and assets.

It is important to keep in mind that the Soft sensor’s algorithm has to represent the system’s dynamics adequately. This ensures that the Soft sensor data is accurate and reliable.

Soft sensors generate additional insights about your process and assets based on elaborate mathematical algorithms. There is another benefit of using Soft sensors when it comes to increasing reliability of your critical processes. Since Soft sensors use algorithms and are capable of receiving and transferring information both ways, you can use them to create additional control mechanisms closer to critical assets. For example, a Soft sensor picks up suddenly increasing temperature in a thermal cracking process, leaving minimal time for reacting to the plant operators.

A fully optimized Soft sensor can give precise indications about the nature of the problem, what needs to be done, and potentially fix the problem automatically by shutting down the valves and controlling the flow to the tank.

In general, in all industries where safety (petrochemical, Oil & Gas etc), material savings, and continuous fast production are fundamental, Soft sensors’ relevance is significantly high.

Get APM Studio e-book

Download our e-book to learn what UReason can do for you, find the unique functionalities of our next-gen APM software, look at the big data analytics framework and learn the different asset analysis models.