How to Identify Unplanned and Unnecessary Downtime

UReason and Endress + Hauser both members of the Open Industry 4.0 alliance, provided a joint lecture based on a Netilion rollout at a Dutch chemical factory

On February 3rd 2021, both organisations presented a case on how best to identify unplanned and unnecessary downtime to reduce recurring calibrations. The presentations are in Dutch.

In the first lecture, Endress + Hauser presented an action plan on how a ‘smart plant’ can be created, based on the NAMUR Open Architecture (NOA) concept, where relevant data for further insights and analysis go towards a cloud-based ecosystem.

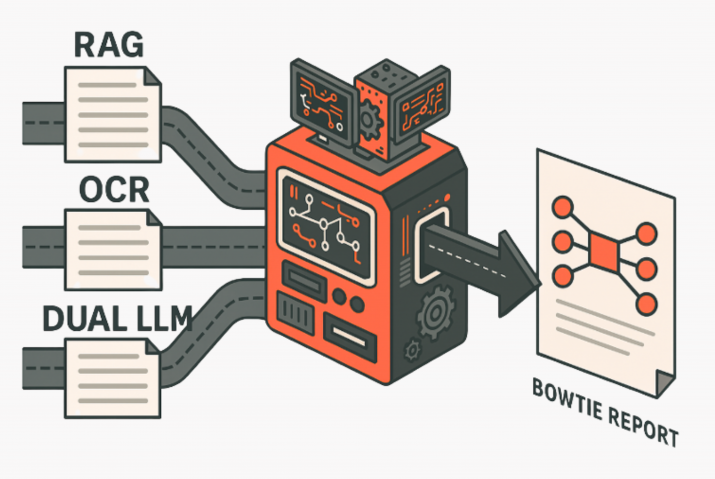

A second lecture was presented by UReason, which outlined how this data can be easily integrated into their APM Studio software via standardised APIs. Based on asset degradation and forecasting models, additional and new insights were provided with which process and quality deviations can be prevented in a timely manner.

Watch the replays of all the sessions held during the PPA Online Knowledge Days!

Watch the Replay of the Joint Case Study!

Learn how best to identify unplanned and unnecessary downtime to reduce recurring calibrations.