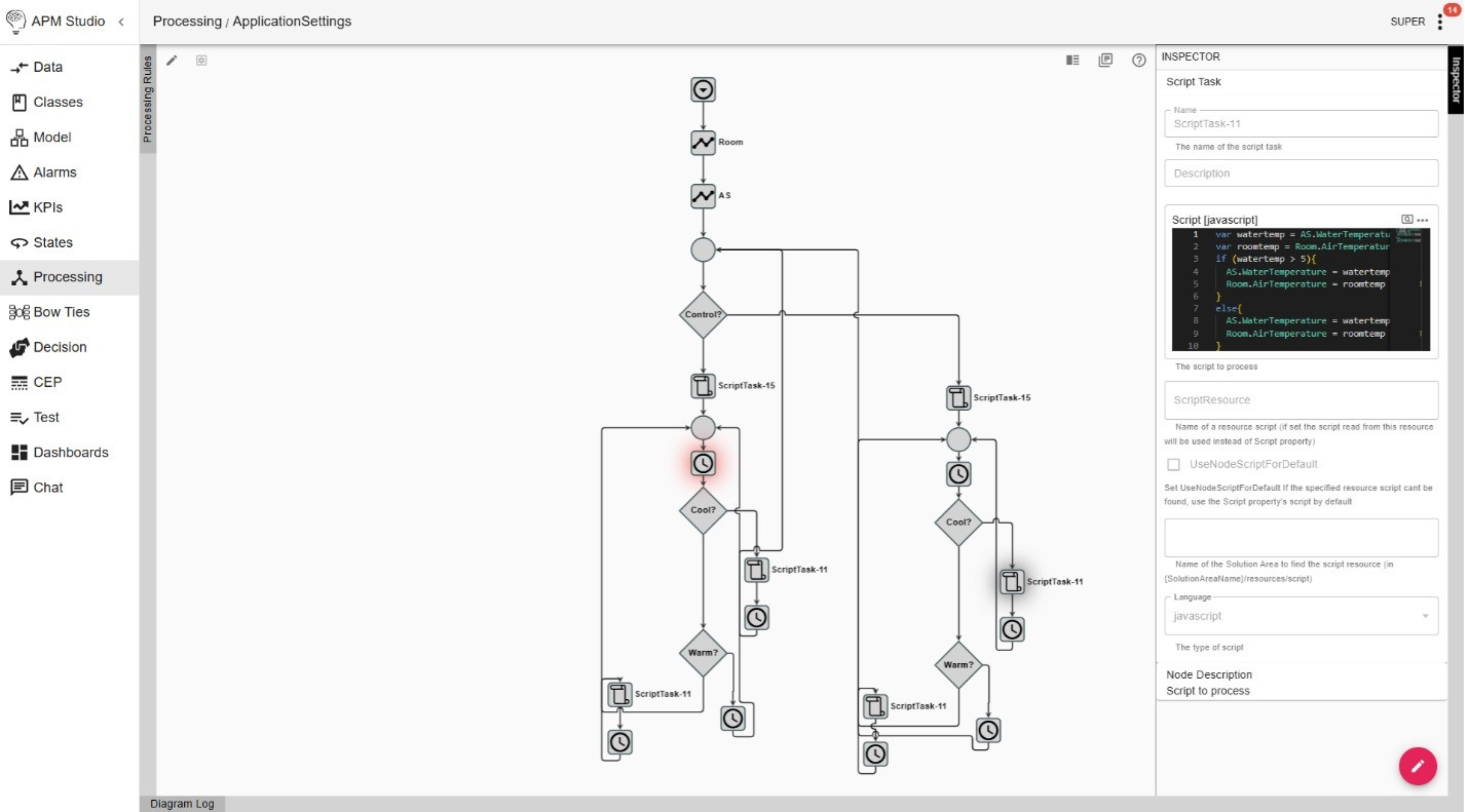

APM Studio enables you to create responsive applications that not only analyze incoming data but also act on it – instantly and intelligently. Whether you’re embedding custom Python or JavaScript code, blending deterministic models with AI, or leveraging live Bowtie Models for real-time risk management, APM Studio ensures that your data pipelines are always ready to process and react.

Productize Your Python or JavaScript Code With Minimal Effort

- Multi-Language Environment: Write custom logic in Python or JavaScript within APM Studio. With GraalVM integration on the horizon, you’ll soon unlock additional language options (e.g., Ruby, R, etc.).

- Seamless Integration: Easily embed libraries like NumPy, Pandas, Scikit-learn, TensorFlow, or your favorite JavaScript packages directly in your data workflows.

- Instant Deployment: Eliminate the complexity of separate infrastructure—your scripts run where your data lives, simplifying updates and version control.

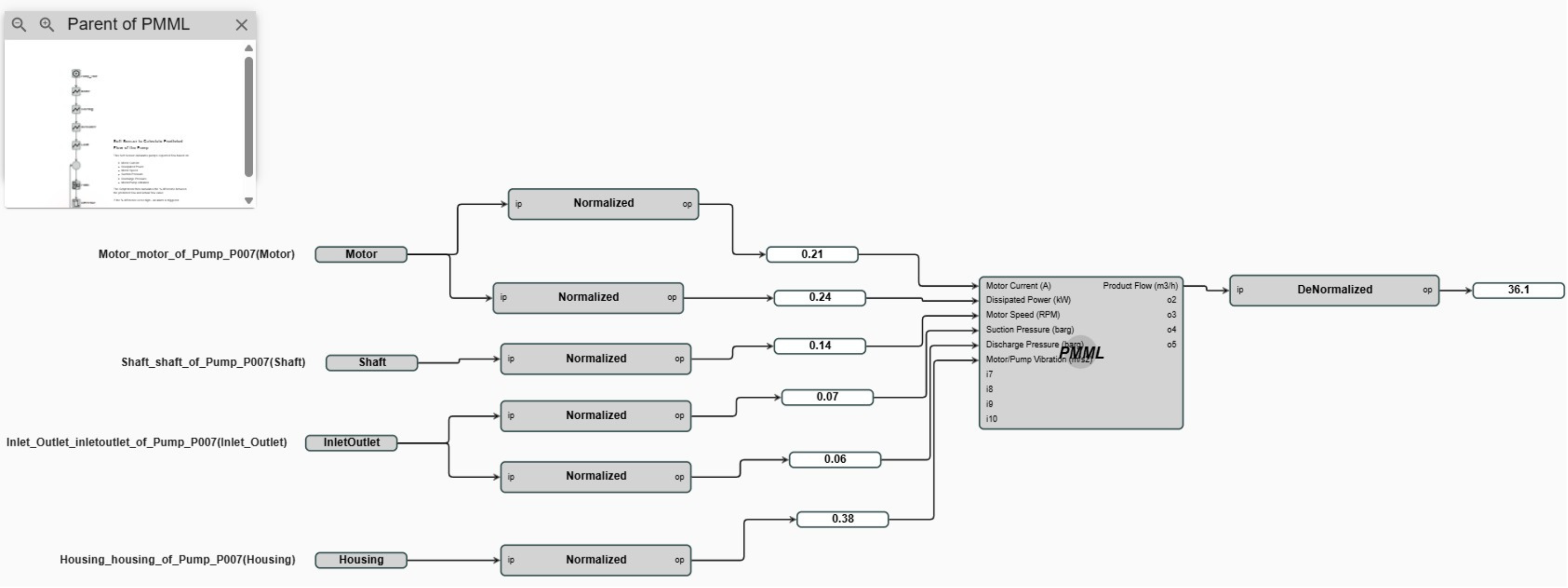

Mix Deterministic Models With AI and Probabilistic Models on Streaming & Historical Data

- Hybrid Approach: Combine rule-based or fuzzy logic (deterministic) with machine learning (probabilistic) for richer insights and more robust decision-making.

- Real-Time & Batch: Integrate high-frequency sensor data or historical datasets for immediate anomaly detection and long-term trend analysis.

- Advanced Analytics: Draw on state models, cause-consequence diagrams, and complex event processing (CEP) to power advanced predictive maintenance, condition monitoring, and more.

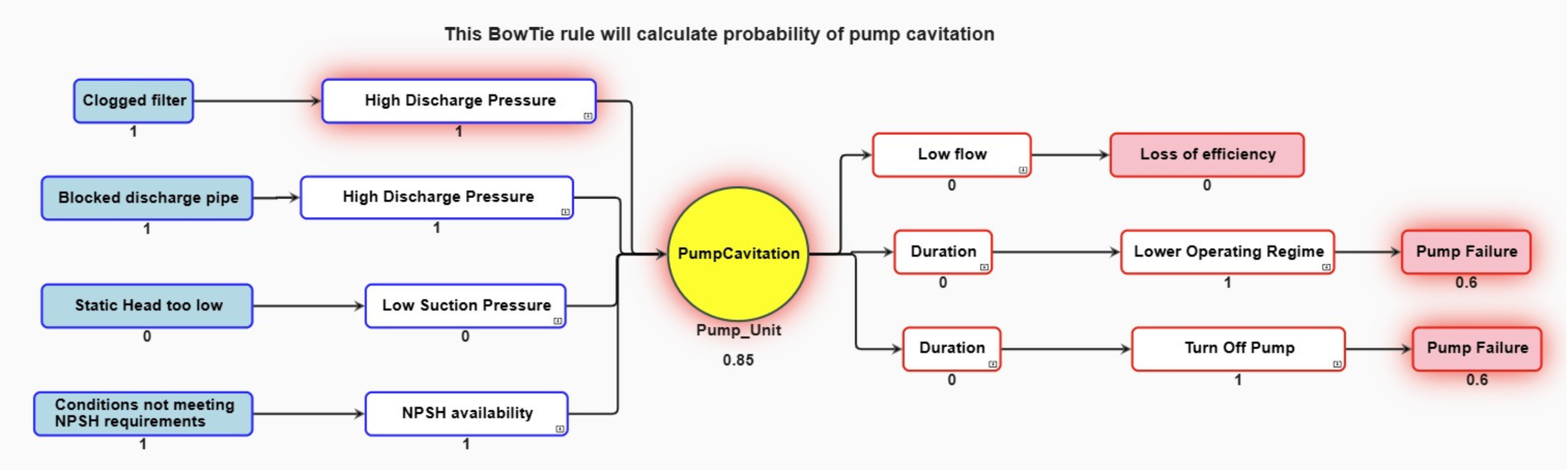

Enhance Risk Management With Live Bowtie Models

A Unique APM Studio Feature

APM Studio stands out by connecting Bowtie Models directly to live, streaming data, enabling data-driven risk assessments in real-time. Originally designed for high-risk industries like aviation, chemical, and petrochemical, Bowties visually represent causes, unwanted events, and consequences—all in one intuitive diagram.

- Dynamic Cause-Consequence

Map real-time data (e.g., from OPC UA, REST, MQTT) to each cause, so you can instantly detect when an event is becoming likely. Likewise, identify potential consequences—such as equipment failure or production downtime—and set up responsive controls to mitigate further damage. - From FMEA to Live Bowties

Transform existing FMEAs or FMECAs into live Bowtie Models by following a straightforward mapping process:

1. Identify your central unwanted event (e.g., bearing failure on a pump).

2. Assign causes (load, fatigue, temperature) to the left side, each with data-driven preventative measures.

3. Assign consequences to the right side, along with barriers or procedures to reduce the impact if the event occurs.

4. Link each Bowtie element to real-time data streams and metrics in APM Studio. - Risk Assessment at a Glance

Bowties deliver complex logic in a graphical, easy-to-understand layout. Decision-makers can see, in real-time, which barriers or controls are weakening and where immediate attention is needed. - Automated Alerts & Actions

Because your Bowties run on live data, APM Studio can automatically trigger alerts or operator guidance whenever a threshold is crossed—helping you prevent or quickly respond to unwanted events.

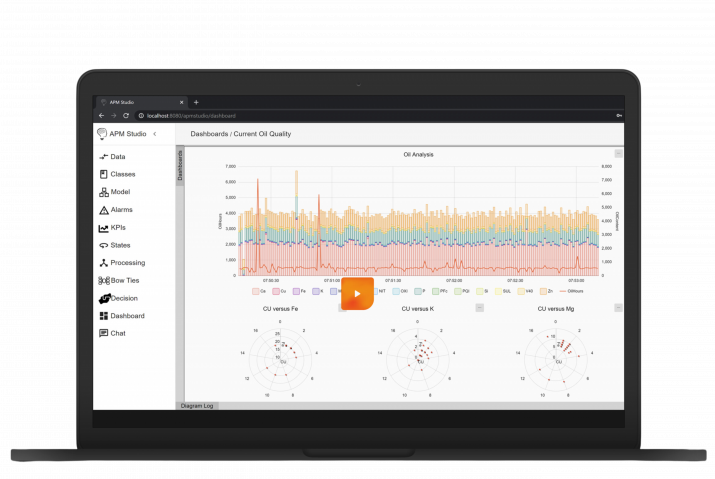

Orchestrate Actions & Workflows Seamlessly

- Real-Time & Event-Driven Processing: Use Complex Event Processing (CEP) to correlate multiple events/alarms and infer patterns or root causes.

- Scalable Architecture: Deploy on Docker, Kubernetes, or cloud platforms like DigitalOcean for automatic scaling—spinning resources up and down as workloads fluctuate.

- Integrated Notifications & Output Channels: Send alerts to maintenance teams, update dashboards, or push insights to existing systems (SAP, Maximo, Slack, Teams, ThingWorx) in real-time.

By blending custom scripting, AI/ML, and live Bowtie Models in APM Studio, you can process and react to operational data with unparalleled speed, clarity, and intelligence. Whether you’re creating predictive maintenance strategies, automating risk assessments, or orchestrating enterprise-wide workflows, APM Studio ensures you’re always one step ahead of the next event.

Ready to take the first step?

Book a call with Artur Loorpuu, Senior Solutions Engineer in Digitalization, who specializes in turning industrial challenges into practical digital solutions. With deep expertise in digitalization and process optimization, Artur collaborates with clients in the process industry to reduce costs, enhance efficiency, and drive innovation.

Let’s explore how we can support your goals!