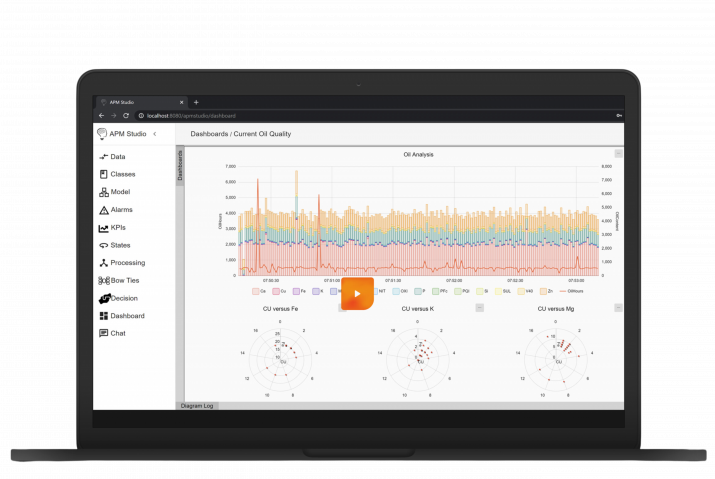

This short tutorial shows how you set-up an OPC UA Client connection to an OPC UA Server. The tutorial uses the Prosys OPC UA Simulation Server.

The tutorial shows:

- The creation of a Data Definition;

- The configuration of the EndpointURL of the OPC UA Server;

- The setting of the SecurityPolicy, MessageSecurityMode and AuthenticationSettings; and

- The configuration of IO-points, OPC Items, to read from the OPC UA Server.

As data flows from the OPC UA Server into APM Studio it is mapped, using specific Mapping, to an object and the build-in Data Viewer is used to view the data.

Background information

The OPC UA protocol (Open Platform Communications Unified Architecture) is an industry standard for the exchange of information and services that is both secure and independent of equipment types, manufacturers and operating systems.

OPC UA is developed and maintained by the OPC Foundation and is supported by many software vendors, Edge devices, PLCs, SCADA, DCS systems, Historians and IoT platforms.

Besides the standardisation of communication between machines and systems, the OPC UA protocol is above all designed to ensure the security of data exchanges in both intra and inter industrial equipment architectures.

The key features of OPC UA:

- Interoperability – Works across different vendors and platforms.

- Security – Supports encryption, authentication, and access control.

- Scalability – Suitable for small sensors to large industrial systems.

- Platform Independence – Runs on various operating systems and hardware.

- Information Modeling – Enables complex data structures and semantic representation.

- Service-Oriented Architecture (SOA) – Uses client-server and publish-subscribe communication models.

The use cases for OPC UA are diverse:

- Industrial IoT (IIoT)

- SCADA (Supervisory Control and Data Acquisition) systems

- Manufacturing execution systems (MES)

- Cloud-based industrial applications

It replaces older OPC standards like OPC DA (Data Access) and OPC HDA (Historical Data Access), making it a future-proof solution for Industry 4.0 applications.