Points covered in the first 40 minutes:

- The BowTie method

- How to use BowTies in the maintenance domain

- A step-by-step example

BowTies in the Maintenance Domain

UReason’s field of operation is real-time condition monitoring and predictive maintenance, working to help customers gain insights from data from their assets and processes. The team at UReason combines domain knowledge and expertise with software to help customers go from data to solutions.

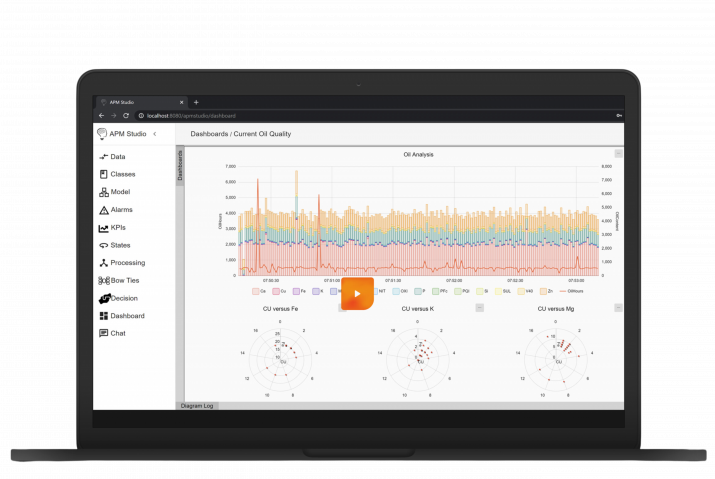

Our software, APM Studio, is used at different levels in the automation pyramid.

It can be embedded, with OEMs (original equipment manufacturer), monitoring faults and risks in isolation to the asset. An asset can be an instrument, a pump, a compressor, a filter, etc. We also work at Levels 2 and 3 where APM is used to monitor faults in relation to the process. At Level 4, APM Studio is used for optimising maintenance costs and planning associated with an asset base supporting a process. APM Studio serves as a single software solution that can be used from embedded levels to the Cloud, for different purposes and users.

Bowties can be applied to the maintenance domain; in both condition-based and predictive maintenance programs supporting you in your decisions balancing risks and costs:

Bowties evolved from different ways to visualise cause and consequence relationships. The first publication on Bowties was in early 1990’s, by Shell, showing how Bowties can be used to structure risk mitigation. Bowties are both easy to understand and highly valuable in condition monitoring and predictive maintenance.

The causes or sources of an event may have one or more preventive controls, that have been put in place to prevent the event (risk) from happening. Similarly, the consequences of the event have a number of responsive controls, or barriers, to prevent or delay further consequences.

In APM Studio, you can set up Bowties and find the monitoring controls for data and models:

You can also run machine-learning models. Once the Bowtie is activated and becomes live, the monitoring controls are continuously looking at data streams. Based on the cause-control outcomes the BowTie can calculate the likelihood of a certain event happening.

Check out more of our webinars

If you enjoyed this content, check out more of our webinars on several topics related to Asset Performance Management!