The monitoring kit detects unwanted issues in real-time and reports them automatically to the customer’s computerized maintenance management system (CMMS), allowing rapid response by maintenance personnel. The result is increased uptime and better insight into the performance and health of rotating assets.

Balluff is known worldwide for high-quality sensor, identification and image processing solutions, including network technology and software. The easy-to-install CMTK from Balluff offers high flexibility through the connection of up to four arbitrary IO-Link sensors and through plug and play system commissioning. The software integrated on the base unit enables automated evaluation and visualization of the collected data. CMTK comes with independent data storage, support for easy data communication through MQTT, and the option of installing a variety of software packages directly on the device.

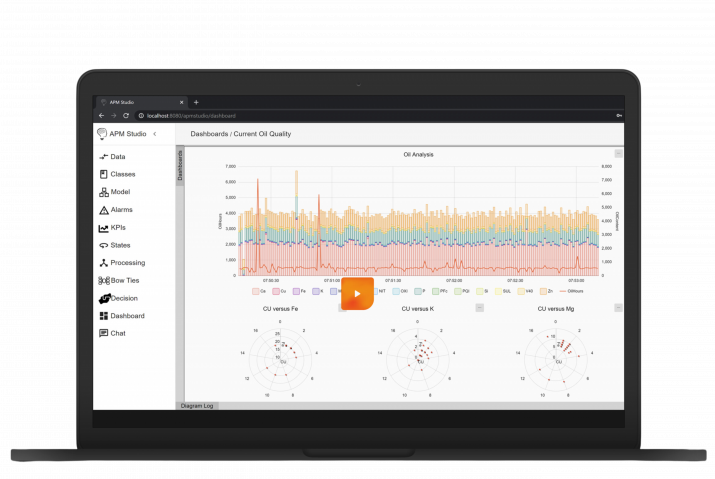

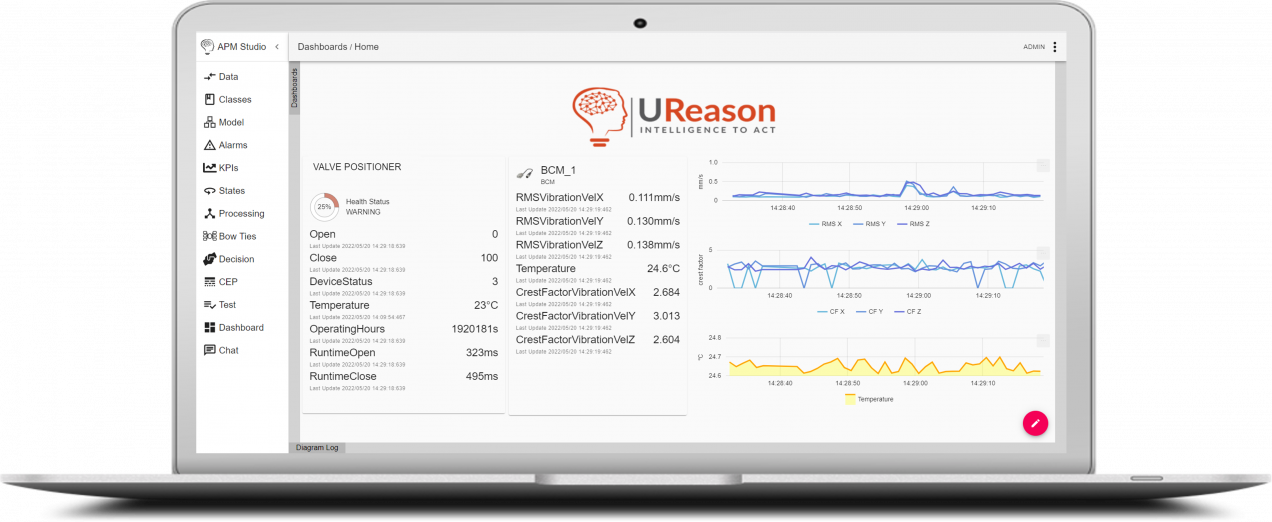

UReason’s APM Studio software provides real-time condition-based monitoring and predictive models, allowing industrial companies to continuously monitor their rotating assets with advanced analytics and monitoring capabilities. APM Studio bundled with the CMTK provides reliability engineering cause-consequence and Artificial Intelligence models, combining advanced modelling with state-of-the-art condition monitoring. APM Studio enables the creation of various outputs, from dashboards, notifications and alarms, to automated work orders for the CMMS (SAP, Maximo, Infor EAM, Ultimo, Upkeep), closing the loop to automated maintenance management.

By bundling APM Studio from UReason with Balluff’s CMTK, UReason is supporting industrial companies in the digitization of their maintenance strategies through an easy-to-install and easy-to-use advanced condition-monitoring analytics application.

Do you want to learn more about APM Studio bundled with the CMTK?

Contact us to learn more about this easy-to-install and easy-to-use advanced condition-monitoring analytics application.