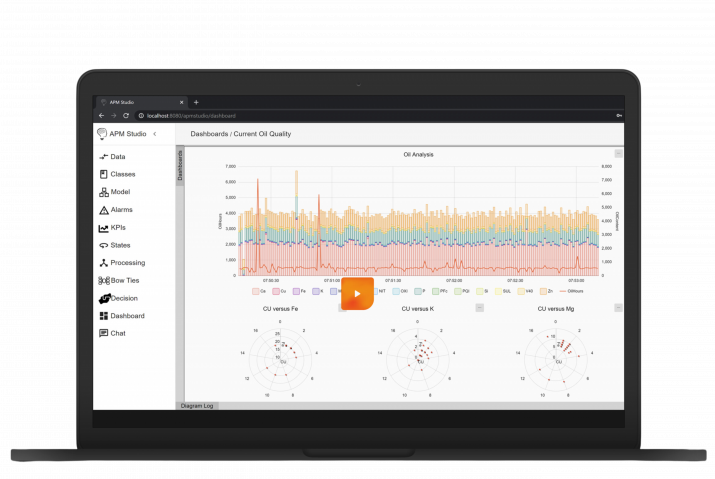

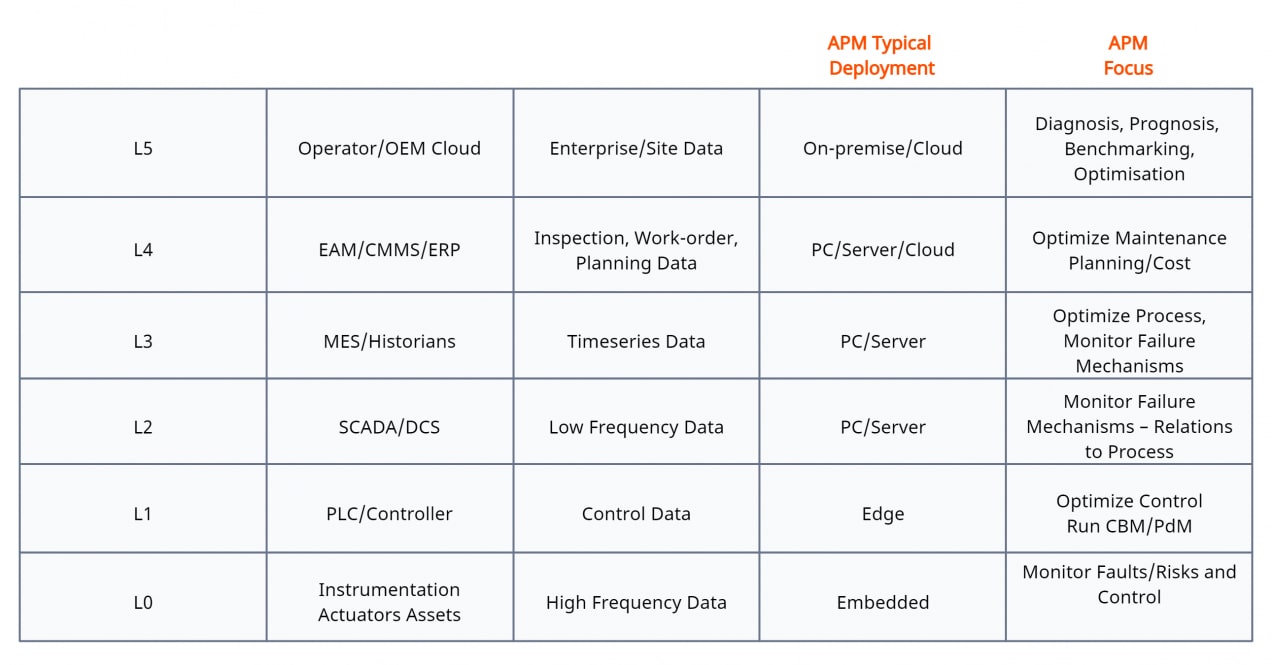

APM Studio is used at different levels in the automation pyramid:

- Embedded, typically in close corporation with OEMS, monitoring Faults and Risks in ‘isolation’ to the asset.

- At the Edge, processing asset data of one or multiple assets to run condition monitoring and predictive applications near to where the data is generated.

- At Level-2 and Level-3, where APM is used to monitor faults in relationship to the process, deployed/running on on-premise compute.

- At Level-4 and Level 5, APM-Studio is used for supporting Reliability as a Service, optimizing the maintenance costs and planning associated to an asset base supporting a process.

An example of Embedded deployment is the FOCUS-1 control valve where APM/APM-Studio provides the diagnostics, prognostics and real-time control. The development of the application logic is done on window platforms and transferred/flashed onto the eMMC of the device in production. A hardened CM3 module in the control valve runs the head-less APM application as well as communication modules for interfacing with the embedded Krohne and Samson devices.

When deployed at the Edge, APM/APM-Studio is provided as a Docker image. Edge devices from WAGO, Different models from Phoenix Contact and many other vendors that support Docker deployment either on their PLC or Edge computers such as Hilscher’s devices are supported. Development of the application can be done on windows platforms or directly on the Edge device. Streaming data from MQTT, OPC UA and many other interfaces are supported. An example of a packaged application is the Pump Health Monitoring App on the PLCNext Store.

When deployed at Level-2 and Level-3, the APM application integrates tightly with the OT and IT applications of the end user. Data can come from:

- Control systems: DCS/SCADA, such as Honeywell Experion PKS, Siemens PCS7, Emerson’s Delta-V, ABB’s 800xa via OPC UA, MQTT, Modbus, etc;

- Data historians: Storing time-series data, and sometimes alarm and event data, of your processes and assets, such as AVEVA’s PI, Aspentech’s IP21, Rockwell’s FactoryTalk, Yokogawa’s Exaquantum, InfluxDB and many more;

- Data bases: Storing time-series data, configuration data, alarm and event data, of your processes and assets, such as Microsoft’s SQL Server, ORACLE, MySQL and PostgreSQL;

When deployed at Level-4 and Level-5, APM has data access to cold/warm/hot path data in Azure and AWS and specific vendor OEM solutions such as Endress & Hauser’s Netilion but also to Enterprise Asset Management and Maintenance Management Systems: such as: UpKeep, Fluke’s eMaint, IBM’s Maximo, SAP-PM, IFS-Ultimo and Infor, typically using the REST-APIs. But also our Control Valve App, which is based on APM/APM-Studio, runs on-premise, in private cloud solutions of our customers and as SaaS managed by UReason.

Check Out More of Our Articles

If you enjoyed reading this article make sure to check out more articles on our website!