Stiction in a control valve is a term used in the field of process control and automation. It refers to the static friction or resistance that prevents a valve from moving smoothly and immediately when a control signal is applied. Hence stiction is the combination of the words stick(ing) and friction 😉.

Stiction can be a significant problem in control systems, especially when precise control is required. It is one of the main causes of control oscillations.

Now stiction can occur for various reasons, including:

- Mechanical Friction: This is the friction between moving parts of the valve, such as the stem and the valve seat. This friction is inevitable but over time, wear and tear, corrosion, or the presence of foreign particles can increase mechanical friction.

- Seal Friction: Valves often have seals or packing materials to prevent leakage. These seals can create additional friction, again inevitable but it can increase especially if they are too tight or dry.

- Lubrication Issues: Insufficient or improper lubrication of moving parts can lead to increased stiction.

Irrespective of the reasons, the presence of stiction can result in sluggish valve response, which can lead to poor control performance in a process control loop (especially with air operated actuators). In extreme cases, stiction can cause oscillations or instability in the control system.

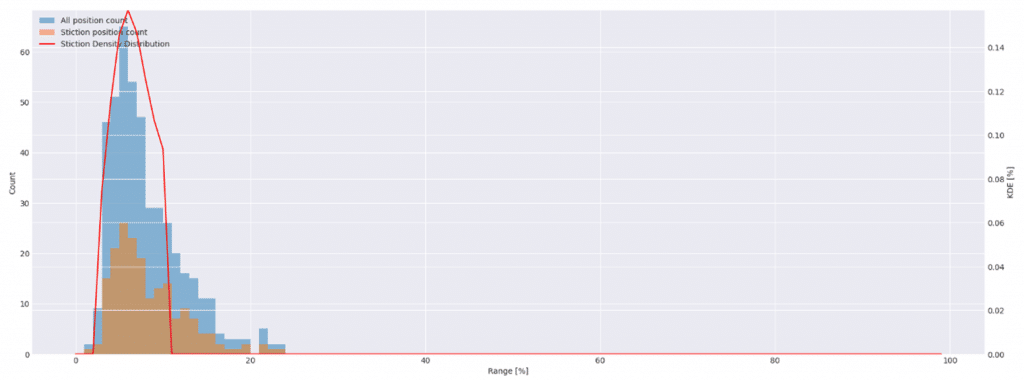

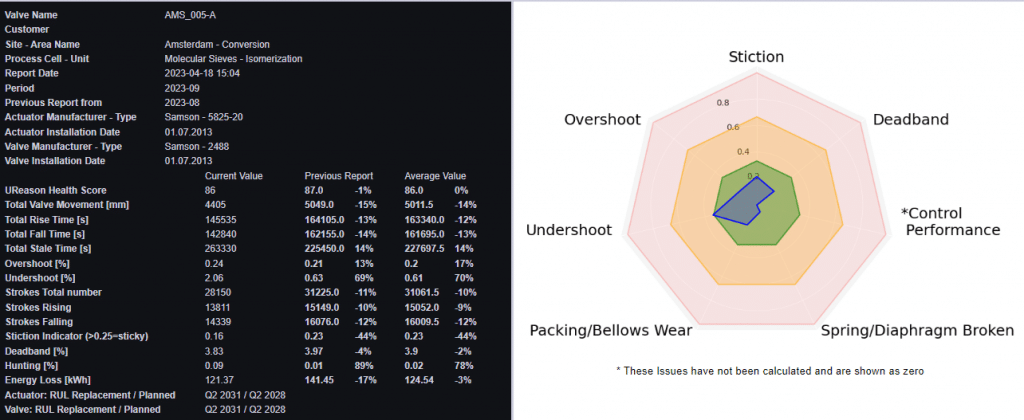

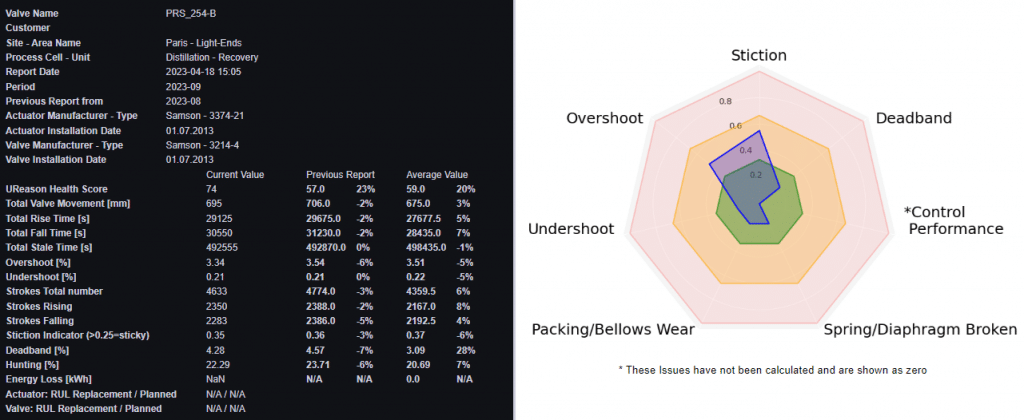

Instead of being confronted with the results of stiction you want to have an early indication of the presence of stiction in your control valve. This is where the Control Valve App comes in. It detects and reports the degree of stiction to its users relative to its operating range:

The CVA does this based on a pattern recognition technique that describes the movement of the valve – e.g. dead band (normal), slip-jump, increasing, steady, decreasing and combinations thereof in a qualitative manner. Using the time-series data of the valve: setpoint and position CO/MV, SP/MV or when position is not available the controlled variable (PV) are used to determine the behaviour and classify the degree of stiction.

The degree of stiction provides not only valuable input for the process/process control engineer allowing them to compensate for stiction (see the overshoot in Figure 3) but also for maintenance to mitigate.

As soon as the degree of stiction goes outward the green centre you should consider lubrication (see Figure 3), check the packing torque and/or potentially replace the packing.

Overall, addressing stiction is essential for ensuring the accurate and responsive control of processes in industries such as manufacturing, chemical processing, and oil refining, where control valves play a critical role.

If you want to see how the Control Valve App works, and how you can best use get started now and request a demo on the basis of your data