Your assets are talking to you in many different ways, all the time. Of course, sensors and analyzers give you the Process Variables (PV) they are supposed to. But there is more, and so much more. Not only do your measurement devices talk to you, so do your other assets. Your rotating machinery, motors, pumps, valves and even your piping are trying to tell you things. If you are like a lot of asset owners and managers, you may not be set up to listen to them.

A generation ago, every process plant or manufacturing establishment had one or more plant experts on staff. Most of these were maintenance technicians or operators, and most of them have retired now. What they could do was remarkable. They would walk around the plant every day during their shifts and listen to the plant talking to them. They would listen for changes in the sounds of the plant. They would put their hands on motors and shaft housings to detect minute changes in vibration and the sound of operation. They could see by watching whether a control valve had excessive stiction or was stuck open or closed. They could tell “by eyeball” if a flow meter was not reading accurately. They could tell which alarms were real emergencies and which could be disregarded. They knew the plant’s operational history because they had lived it too.

What they were doing was sensing change. Change in a PV without a clear cause. Change in the sound of flow through a pipe that might indicate a corrosion problem. Change in vibration from a motor or a bearing indicating excessive wear. They could hear, see, and feel change as the plant was run and products were made. Now they are gone, or almost all gone.

For years, the plant operators and maintenance people noted these changes on paper, and most elderly plants have stacks and stacks of paper records that have hardly ever been looked at since the day they were first written. It was as if the maintenance and operations staff went out, listened to their assets, and promptly forgot what they heard. At some point in the past thirty years or so, people started to add this data to spreadsheets and then databases so that they could look at asset history and try to derive trends they could use to anticipate asset failures. Often, this is done as a project, and stops when the project money runs out. Many Computerized Maintenance Management Software (CMMS) systems have been installed that way. The problem with most CMMS systems is the adding of, and subtracting of, the latest data on assets. Assets are not stable. Changes occur all the time. And then there’s the ability to predict what needs to have maintenance done and what doesn’t.

The addition of Artificial Intelligence (AI) to the mix means that the system can run without constant attention by the maintenance people and operators. And an AI can be trained to listen to the assets in the plant, just like your employees used to be able to. Yes, people can do that too, but an AI can do it without being distracted and pulled off the job to do something else. AIs have immediate access to asset operations history, and they can look at very long baselines of data to determine if there is a problem coming, and predict when it might happen, and what needs to be done to prevent it. This is called predictive maintenance and is the way plants get to 100% uptime.

Programming AIs is seen as a limiting factor to their use. Data scientists are needed, and they aren’t inexpensive to hire, and they need to be trained on your plant so that they know what the data means.

Remember, we started this by asking if you have been listening to your assets. A major problem with this is that there are dozens of manufacturers of meters, valves, pumps and motors, motor control centers, and PLCs and distributed control systems. Each plant is like a Tower of Babel with each manufacturer having slightly different languages in their types of devices. AIs can be trained to “speak” each of these languages so that they can understand a flow meter and a control valve of two different manufacturers.

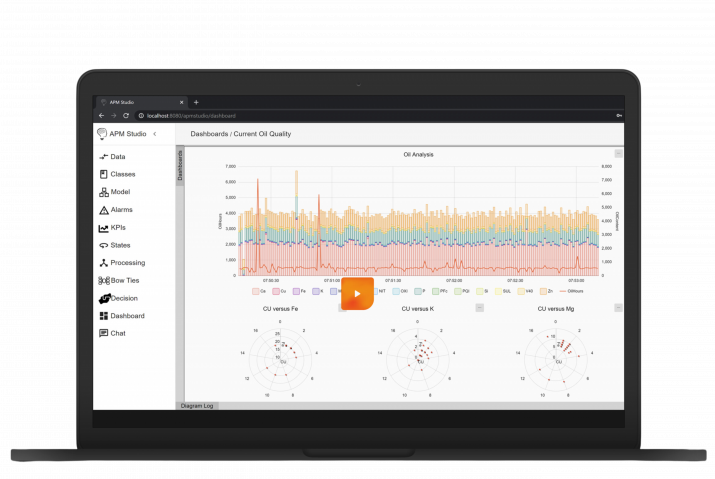

The answer for you is to let a properly trained AI listen to your assets for you. UReason’s APM Studio can begin by making your assets smart and speak the same language, producing real-time condition-based monitoring and predictive models. APM Studio can make your assets run autonomously, with UReason’s decision support capabilities. And it is easy for non-data-scientists to learn to use.

What does this mean for you? It means that you can operate your plant at a higher level of production than ever before, because you aren’t suffering from unexpected major maintenance issues. It means you can make more money. Nobody can disagree with that.

Click here for an eBook that explains how this works, and click here to have a UReason APM expert contact you for a demonstration.